motan-colortronic shows

the latest developments

in the medical

area during MEDTEC

Intelligente Kommunikation

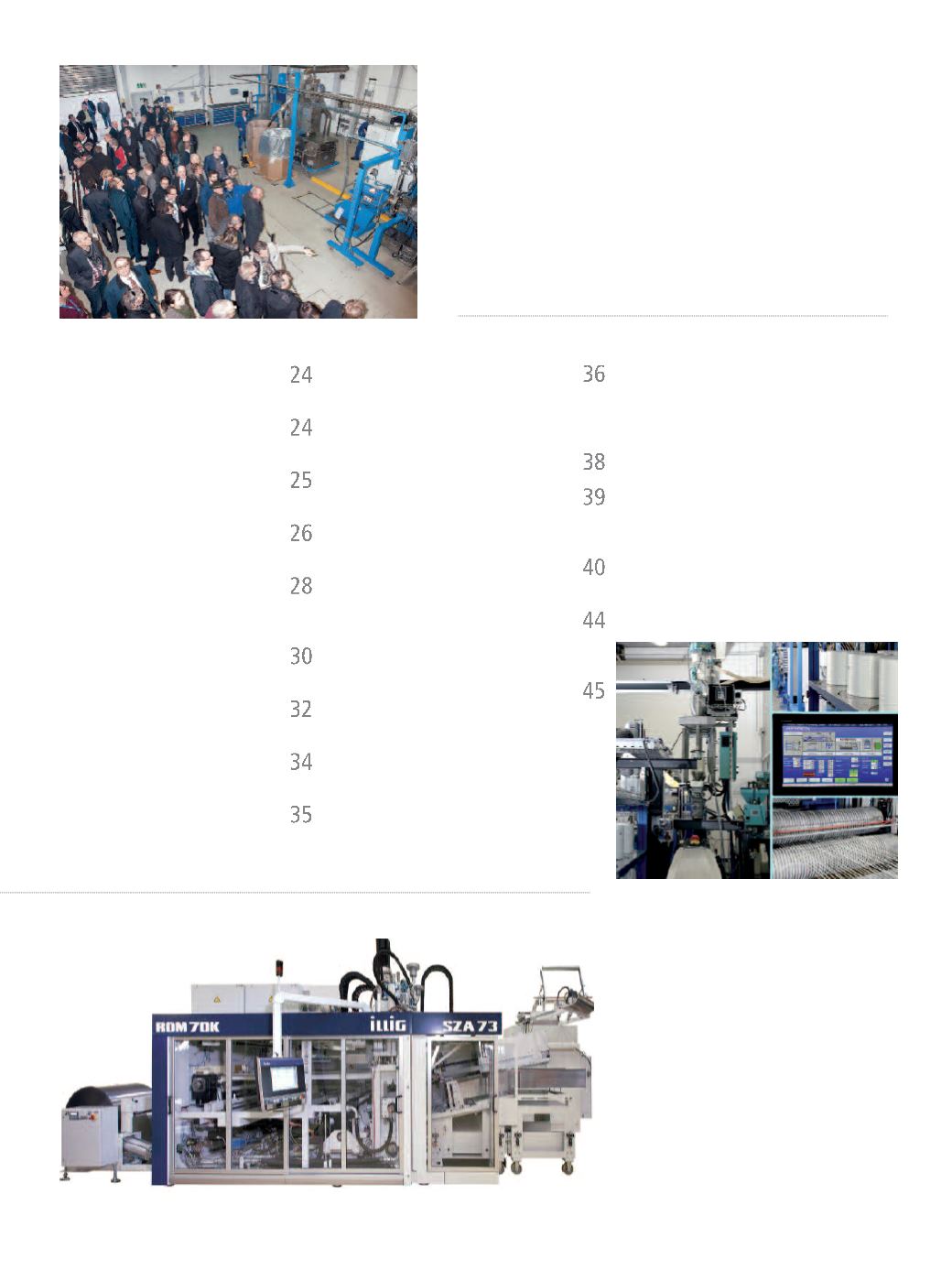

Thermoforming Line

for Drinking Cups

with IC-RDM 70K

“Grinders alone

are no longerenough!”

Trends and developments

in the Asian Flexible

Packaging Market

IKV meets the world in Aachen

The new compounding extruder

installed in the LFT development plant

at Bensheim with its co-rotating,

26 mm diameter twin screws is

designed for throughputs of up to

150 kg/h. Installed upstream of the

extruder is a SOMOS® Gramix S

gravimetric dosing system for

accurately dosing and mixing

of up to nine components.

Page 34The ILLIG IC operating concept also

supports the aspects relevant for

large-volume production very effec-

tively. Besides modules used for

general process optimization, e.g. the

self adaptive start-up (sas-up) during

material or mold change, mainly IC

modules are employed which ensure

high productivity and reliability of a

production line and at the same time

help to minimize operation costs.

Page 39AMUT for corrugated PVC

sheet complete extrusion line

Coperion Corporation relocates

to new premises

First Bubble Guard® Board

line hitting USA market

ZE BluePower twin-screw extruders

attract great interest from customers

Material and energy saving

in thermoforming sheet, pipe

and profile extrusion

New Technology

for Breathable Products

Flow control

and versatility of coextrusion

Versatile plant engineering

for high quality LFT compounds

Quality assurance during

the extrusion of big tubes

On the occasion of the TecDay on 24 February 2016

in Hannover, KraussMaffei Berstorff exhibited their latest

twin-screw extruder development – the ZE 65 BluePower

Torque. Being designed for challenging requirements in

high-performance compounding, this new machine

generation is the ideal solution for customers who expect

to achieve unparalleled quality and high performance

combined with substantial energy savings.

Page 26