Extrusion International 2/2016

18

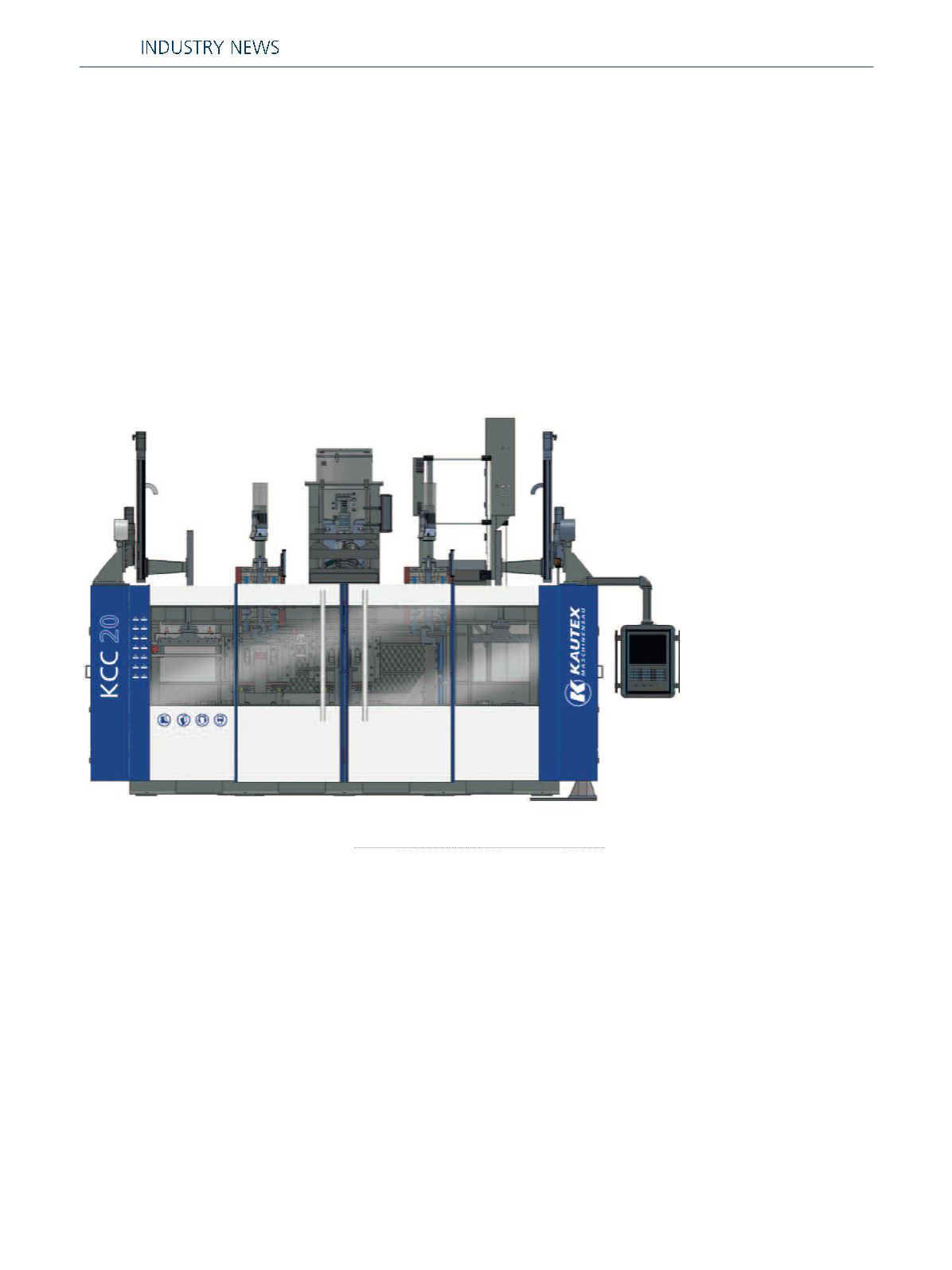

At this year’s Chinaplas, which will be held in Shanghai from

25 to 28 April 2016, Kautex Maschinenbau will present a new

model in its successful KCC series of extrusion blow molding

machines. This is the third generation of the KCC series, which

has been produced in Shunde, China, since 1997.

The new blow molding machine model, which was announced

at the Open House event in October last year, represents a com-

plete relaunch of the KCC series. As well as a number of new

and revised technical features, the machine has also been com-

pletely re-designed, to visually blend in with the look of new

Kautex machines.

Third generation of KCC machines go into production

www.kautex-group.comWith its compact form, the new KCC generation takes up less

floor space in the production hall. Better accessibility not only

makes the blow molding machine easier to service, but also

speeds change over times. Molds can now also be changed from

the side, for example, and products are discharged from the rear

of the machine. A greater standardization of modules and com-

ponents has reduced the investment costs of the new machine

and shortened future delivery times.

New KSB suction blow molding machine

Kautex Maschinenbau will also allow first insights in its new KSB

suction blow molding ma-

chine at Chinaplas. This

brand new machine type

was specially designed for

low-flash production of 3D

molded parts. Global de-

mand for plastic ducts for the

automotive sector is rising all

the time, ever since the use

of special materials such as

PA6.6 or PPS has enabled the

production of highly heat-re-

sistant exhaust ducts.

A modern operating concept

with Kautex BC5 controller

makes the new KSB machi-

nes easy to operate. In addi-

tion, the new suction blow

molding machine takes up

almost 50% less space than

previous equipment, thus re-

ducing investment costs.

Tailored LFT compounds the reliable way

ProTec Polymer Processing's focus at this year's Chinaplas from

25 – 28 April in Shanghai will be on the production of long-fibre-

reinforced thermoplastics (LFT) by pultrusion and on the new ge-

neration of ProTec tumble reactors. These SSP (solid-state

post-condensation) reactors are ideally suited to improving the pro-

perties of flowable plastics. Examples include the post-condensa-

tion of pelletised polyesters (PET, PBT, PEN etc.) and nylons such as

PA6 and PA6.6. These "upgraded" materials are then for example

converted into bottles, fibres and industrial yarns which are requi-

red for optical waveguides, tyre cords and for airbags, fibre-com-

posite materials, filter fabrics or nonwovens. When injection

moulded, LFT compounds with fibre reinforcement along the

length of the pellets result in components which combine high

strength and light weight with very good surface quality. LFTs with

a fibre length of around 12 mm are ideal for further processing.

Flexible, versatile LFT technology

ProTec's LFT technology is suitable for producing a wide range of

materials with differing levels of fibre reinforcement and many dif-

ferent polymer matrix materials which may also be directly com-

pounded during LFT manufacture. Even the difficult pairing of

carbon fibres with PP can be reliably processed. ProTec's head-

quarters in Bensheim (Germany) has a versatile cutting edge pul-

trusion line for application-specific customer testing and basic