Extrusion International 2/2016

19

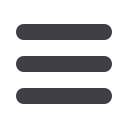

Producing LFT compounds by pultrusion invol-

ves continuously drawing fibre strands through

a polymer melt, so impregnating the individual

fibres with the polymer matrix and, once the re-

sultant fibre/polymer strands have cooled, pelle-

tising them. In order to be impregnated, in the

first process step, the fibre strands are guided

from the creels by a specially designed guide into

the impregnation die. Downstream from the die,

the hot fibre/polymer strands are then finally

shaped, for example into round strands or flat

tapes, in a profiling system. After cooling in a

cooling unit adapted to the polymer, they addi-

tionally pass through a puller which controls the

continuous passage of the strands through the

line.

ProTec is a one-stop shop capable of designing

and supplying complete turn-key lines tailored

to specific requirements from materials develop-

ment to testing and commissioning on the cus-

tomer's premises. The lines are capable of

handling fibre contents of up to 60 wt.% and

throughputs of up to 1,200 kg/h. Any conven-

tional thermoplastics or even biopolymers such

as PLA (polylactic acid) can be used as the ma-

trix, while glass, steel or carbon fibres can be

used as the reinforcing fibres.

The LFT line and all its modules are operated

from the central line controller. Variable parameters include line

speed, extruder throughput and pellet chopping length. Additio-

nal functions, located upstream or downstream depending on ap-

plication, may also be incorporated into the control system. These

include drying, conveying, dispensing and mixing of the feed com-

ponents.

www.maag.comMAAG – 4 STEPS AHEAD FOR YOUR SUCCESS

GEAR PUMPS, FILTRATION, PELLETIZING AND PULVERIZING SYSTEMS

Come and see us at Chinaplas: Hall E1, Booth J21

ProTec's LFT pultrusion technology produces high grade long-fibre-reinforced

pellets with a wide range of polymer matrices and huge variety of reinforcing

fibres. This technology also permits reliable and flexible adjustment of matrix

properties (Photo: ProTec Polymer Processing)

www.sp-protec.comprocess and materials development. A keystone of the line is a

high-performance compounding extruder equipped with a

SOMOS

®

Gramix S gravimetric dosing system capable of accura-

tely dosing and mixing up to nine components. As a result, a very

wide range of individual formulations of the polymer matrix can be

produced very flexibly directly in the process. Recycled material

and additional fillers may likewise be included in the material for-

mulation.