Extrusion International 2/2016

33

www.nordson.comconsistently supply high quality products,” said Aprigio Pinto,

director of production at Evertis de México. “We work with

avant-garde equipment suppliers whom we know we can count

on for excellent customer service and assistance. This philoso-

phy is crucial to Evertis de México, given our continuous growth

in the markets we serve.”

“The immediate responses by the technical support team at

Nordson means that Evertis de México is guaranteed high qual-

ity equipment and service at a competitive price in the market,”

said Jacques Tillet, director of maintenance at Evertis de México.

“At Evertis we produce semi-rigid barrier PET sheet for food and

non-food applications, and it is essential that we maintain layer

uniformity within tolerances at all times. The Nordson EDI die

system allows us to control layer interfaces, and thereby avoid

product defects such as waves. With this system in place we feel

confident that our customers will receive high-quality products

every time.”

Meeting the Challenges Posed

by Asymmetrical Multi-Layer Structures

“Because critical layer interfaces are shifted into higher shear re-

gions of the flow paths, coextrusion instabilities are more com-

mon with structures that are asymmetrical,” said Nordson EDI

chief technologist Sam G. Iuliano. “Our die system yields stream-

lined melt streams and fine-tunes them at the point of conflu-

ence. In addition, the ease with which adjustments can be made

enables the system to be quite versatile in both layer configura-

tion and product width.”

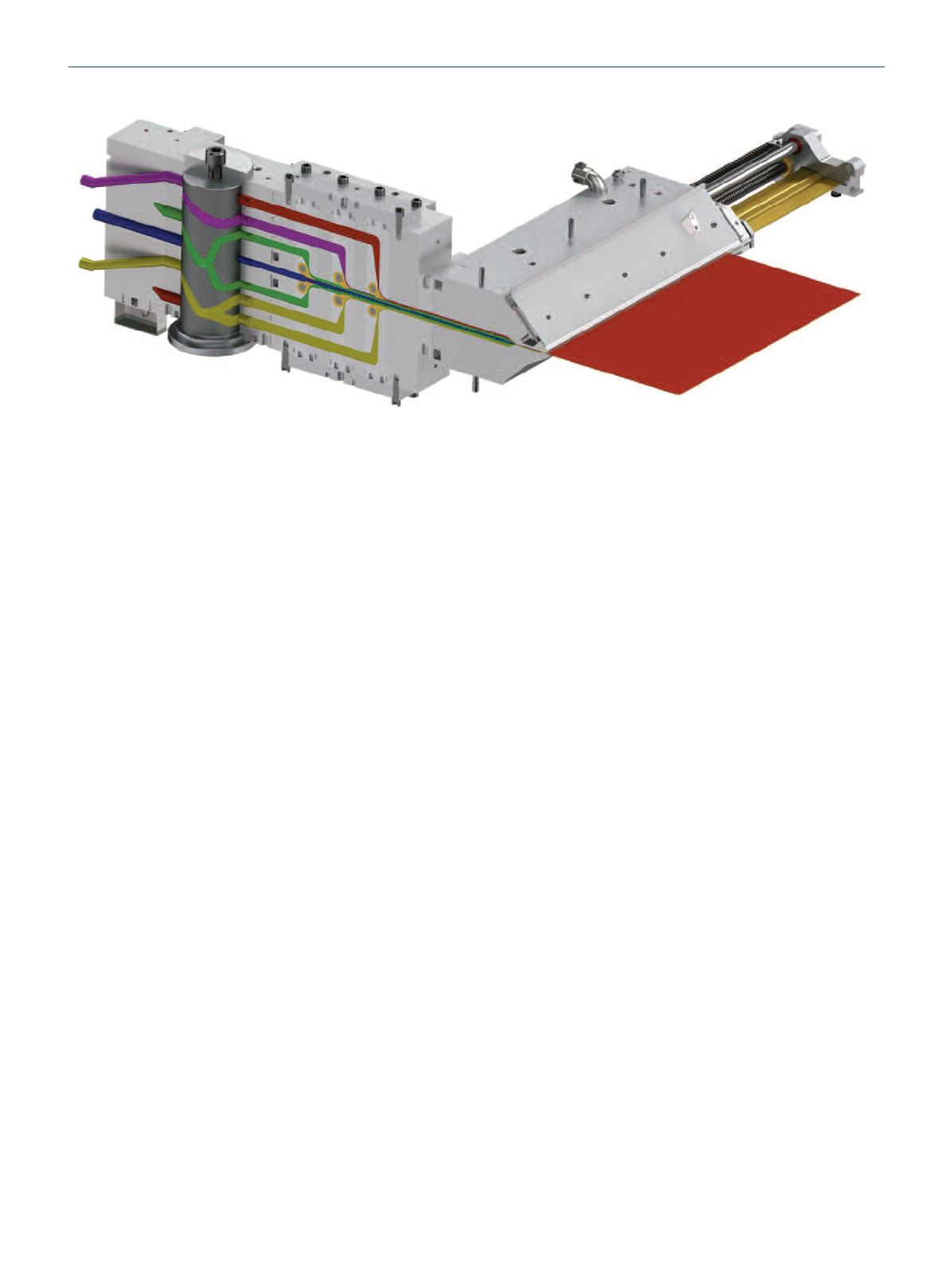

Chief among the components of the Nordson EDI die system

used by Evertis de México are the following:

Ultraflex™ die with Multiflow™ II-G manifold and internal

deckle. Nordson has engineered the manifold, or flow channel,

inside the die to reduce shear stress levels at the layer interfaces,

resulting in improved layer uniformity. At the same time, the sec-

tions of the manifold at each end of the die are sized to ac-

commodate adjustable internal deckles for making changes to

product width.

Ultraflow™ V-S adjustable feedblock. A feedblock combines

melt streams from separate extruders into a multi-layer “sand-

wich” that the extrusion die subsequently distributes to target

product width. The Ultraflow V-S feedblock incorporates ad-

justable “combining planes” located where the melt streams

join the central flow channel. These make it possible to balance

the velocities of the combining streams. When operating in

“free-float” mode, they automatically compensate for the

changes in layer thickness ratios that accompany product struc-

ture changes. Adjustments can be made without taking the

feedblock off-line, increasing up-time and end-product versatil-

ity. Another adjustment that can be carried out on-line is use of

a selector spool that makes it possible to change layer sequences

in the structure.

Evertis de México S.A. de C.V. is a subsidiary of the international

IMG Group, a pioneer in the field of PET film extrusion. In addi-

tion to the plant in Mexico, the group has manufacturing facil-

ities in Brazil and Portugal and sales offices throughout the

Americas and Europe. Evertis de México is located at Ave. Platón

No. 138, 66600 Cd Apodaca, N.L., Mexico.

Tel: +52-81-8386-5550.

Fax: +52-81-8386-5553.

Visit:

http://www.evertis.com/es/home.Photo Caption: Cut-away schematic of Nordson EDI die system

supplied to Evertis de México shows Ultraflow™ V-S feedblock

at left and Ultraflex™ die at right, with internal deckle (bronze-

colored component) projecting from the die. The seven-layer film

structure is asymmetrical, with different materials above and

below the central layer. The cylindrical component in the feed-

block is a selector spool for on-line changes to layer sequence.

The six yellow teardrop-shaped components at points where lay-

ers converge are combining planes for fine-tuning of combina-

tion velocities.