89

Extrusion 7/2016

➠

Rapid Granulator Group

www.rapidgranulator.comK 2016: Hall 9, Booth E19

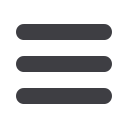

Rapid ”Open Hearted” design and tilt back hopper gives direct and unrestricted

access which drastically simplifies service, cleaning and maintenance

The low cost of ownership of the new

Raptor Series is accomplished through

the ease and speed with which it can be

cleaned and maintained. The machine

can be in a completely open position in

less than one minute after it has stopped

running. Once the machine is open, all

fasteners are accessible from the outside

using air driven tools. The access made

possible by the “open hearted” designs

makes any contamination immediately

visible.

The tilting hopper opens with an electri-

cally operated jack, while the screen and

granule bin can be handled by a single

operator. The screen cradle design does

not require the removal of bolts in order

to remove the screen, and the granule

bin slides out easily. The same tool is

used to unlock the front door and to ro-

tate the rotor. As an option, a light can

be fitted to provide extra illumination.

The FlexiPUSH is a pneumatically driven

pusher and is intended for handling

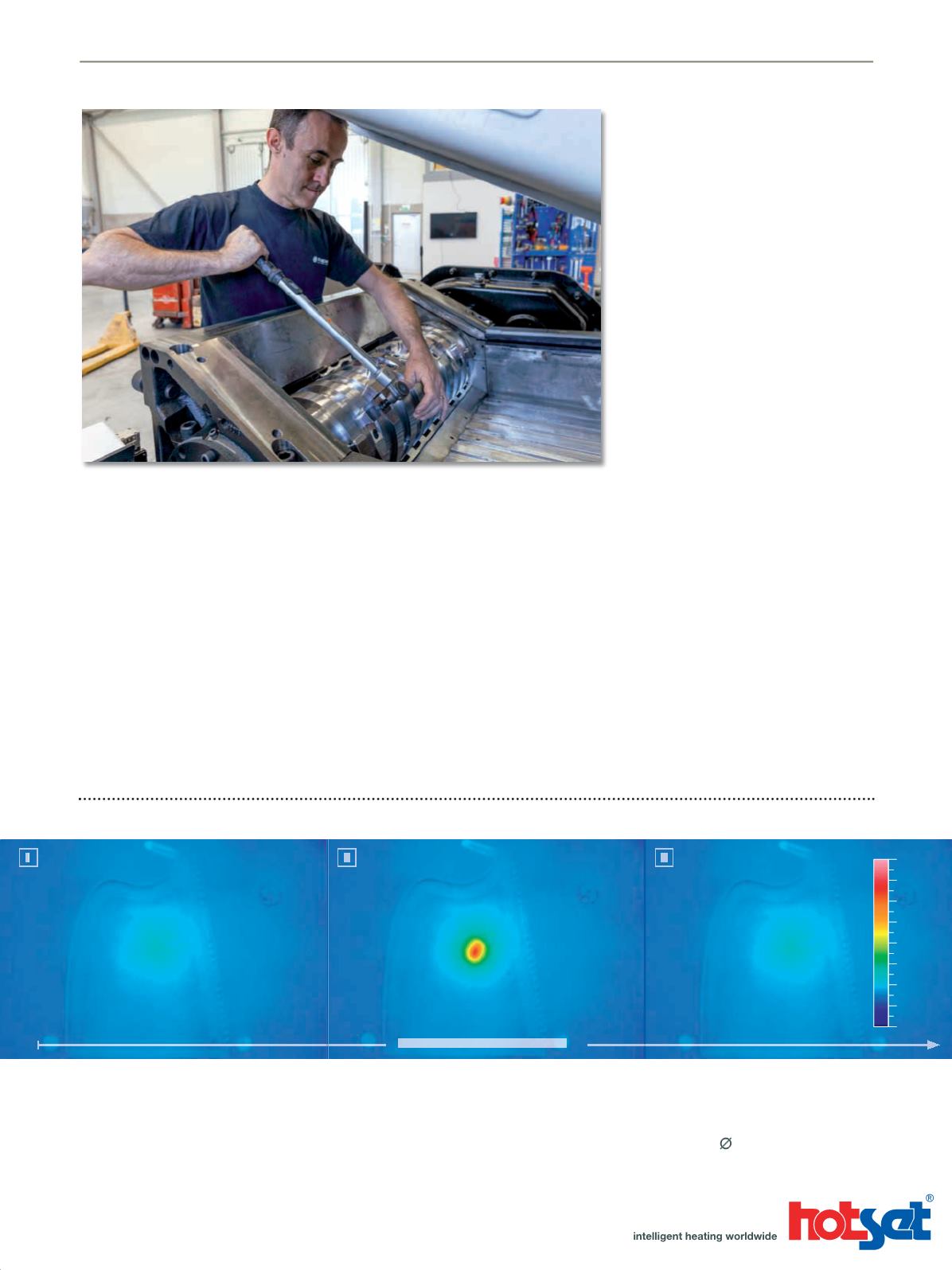

Zensationell!

Partielle, dynamische Kavitätserwärmung mit bis zu 60 K/s

Linien- oder punktförmige Temperierung

Minimale Energiekosten (Beispielwerkzeug „Eiskratzer“

100 W)

Zykluszeiteinsparung

Keine Lizenzkosten

www.hotset.comDas neue Z-System ermöglicht:

Innerhalb von ca. 6 Sekunden

200,0

177,9

155,8

133,6

111,5

89,4

67,3

45,1

23,0

°C

1

2

3

basic applications, including lumpy ma-

terials. It can handle large products such

as a 1200-L IBC (Intermediate Bulk Con-

tainer) for example. The hydraulically

powered PowerPUSH maximizes output

for shredding sheet and film. The cutting

chamber features a textured floor to re-

duce the risk of material adhering or

finding its way under the pusher and is

offset by 5 degrees to enable liquids to

drain away.

The QuadCUT cutting system for general

plastic waste features a solid knife that

allows the full use of all four cutting

edges. The cutting system is extremely

durable and has a rock solid clamping

system attaching the knife to the rotor.

The knives are supported by a sacrificial

washer in order to protect the rotor

should non-plastic material accidently

enter the cutting chamber.

The base of the Raptor Shedder series is

also equipped with the Rapid MCB fea-

ture (Mineral Composite Base) which ab-

sorbs stress and vibration during opera-

tion and gives the shredder a very solid

footing and a low center of gravity.

The Raptors can also be configured in

the Rapid DUO concept, with a floor-

standing granulator located directly be-

neath the output of the shredder.