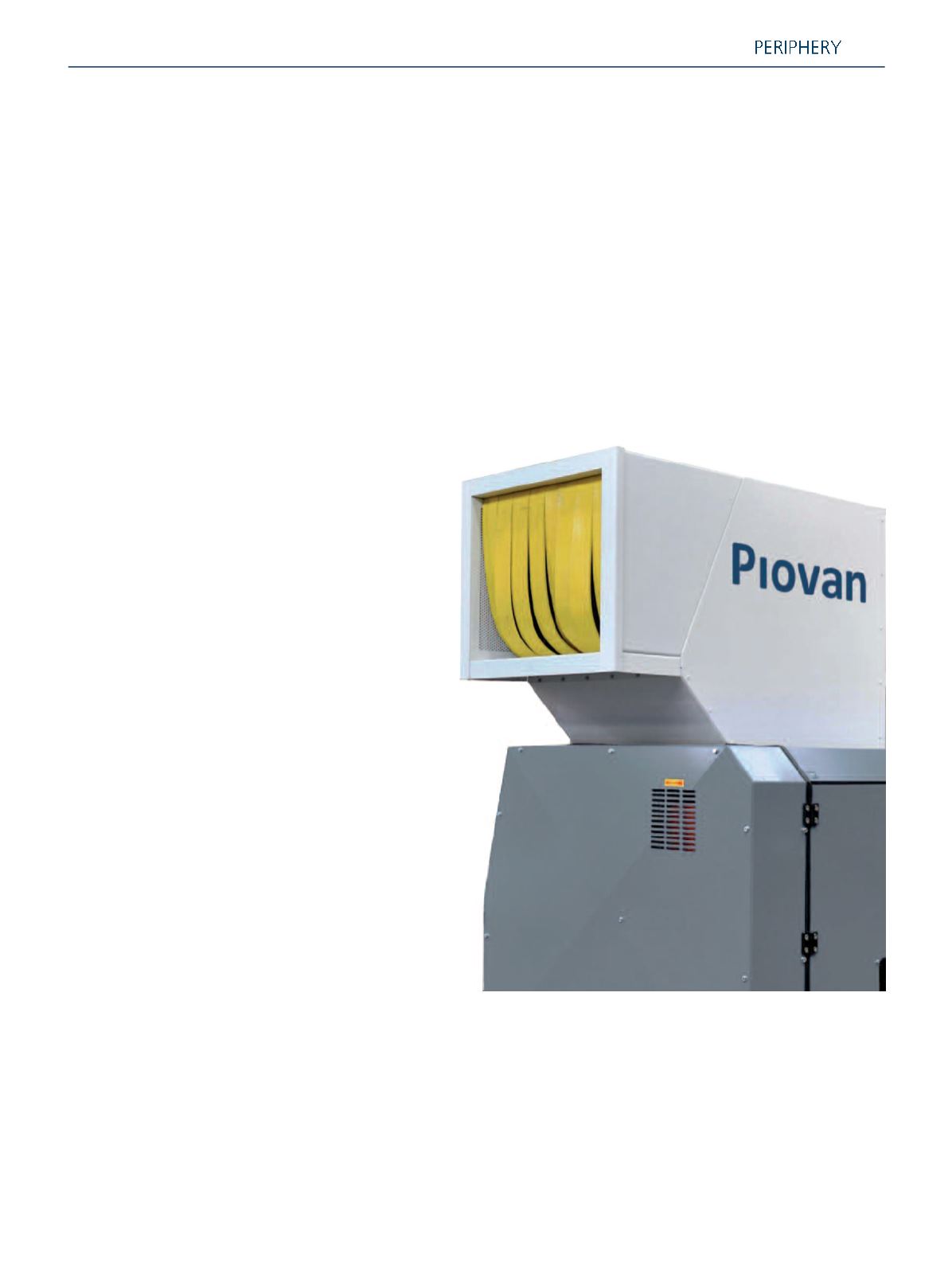

New Range makes its Debut

innovative Technical and Design-Based Features

N

owadays, all industrial products are designed with

a view towards recovering and recycling

as many reject components as possible. In certain sec-

tors, for example in the Food&Beverage packaging

sector, a decision is often made not to change raw

material, in order to continue the existing recycling

channels and methods. The need to develop recycla-

ble materials influences and determines choices in the

research and development sector. For this reason,

granulators have assumed a fundamental role in the

plastics sector, having been specifically designed to

recover plastics processing waste and make it

reusable.

Piovan has redeveloped its range of recycling prod-

ucts introducing very high quality machines able to

satisfy all recycling needs throughout the plastics sec-

tor. In all cases where plastic is used in the packag-

ing, medical, automotive, textiles and electronics

sectors, recycling is common practice, confirming the

need for increasingly efficient and reliable granula-

tors. Piovan has therefore introduced a new range

complete with small, medium and large granulators,

characterised by innovative technical and design-

based features.

Most importantly, all new machines are fitted with an

absolutely unique tangential cutting system. The ro-

tary blades are inclined with respect to the fixed

blades and are positioned as close as possible to the

geometric tangent of the cutting circle, therefore optimising

and improving cutting precision. In this way, high production

capacities are achieved using smaller motors, with the addi-

tional benefit of minimising dust production and heat gener-

ation. These features ensure a more regular cut and more

dimensionally consistent regrind.

Without a cutting chamber of this quality, the regrind, in ad-

dition to being irregular, will also have a higher dust content

and will therefore be more difficult to process.

The new Piovan granulators are a step ahead of current ´

versions available in the market thanks to the

way they are manufactured

The cutting chamber is made from machined pieces, which

are then assembled rather than being cast or welded. This de-

sign has enabled the construction of high-precision compo-

nents that improve the efficiency of the cut and the quality of

Extrusion International 3/2016

41