➠

www.tecnomaticsrl.net

➠

www.tecnomaticsrl.net

Extrusion International 5/2016

22

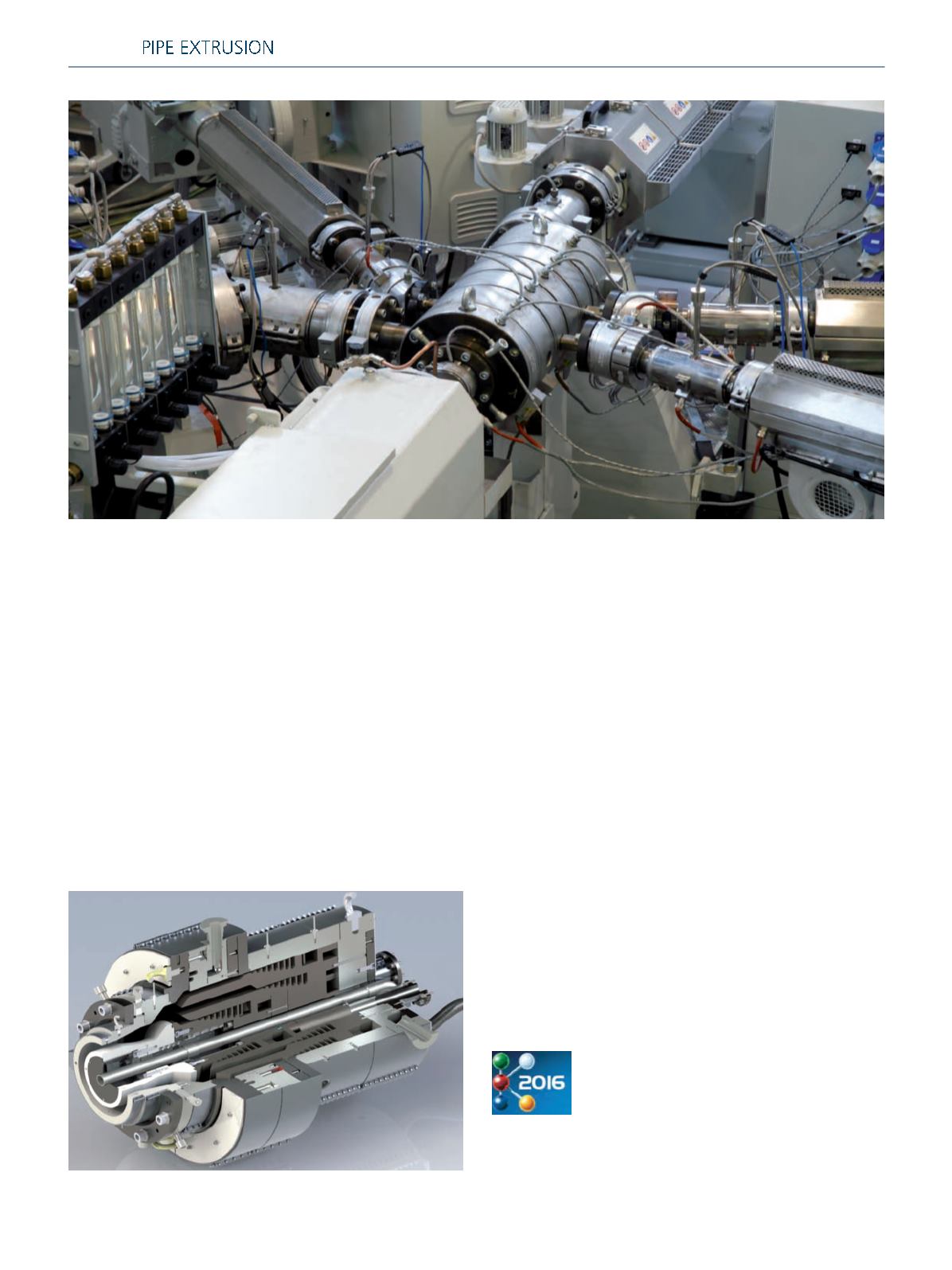

ATHENA MULTI 5-40, for PE-X AND PE-RT

VENUS MULTI 250 QUATTRO – 4 LAYERS

Hall 16, Booth D05

The heart of the VENUS MULTI consists of innovative flow

channels geometry, which has been calculated in considera-

tion of the current raw material PE 100 CR and PP. This geo-

metry assures the same behaviour for pressure and

distribution of the melt in all the pipe heads also at very high

output rate.

The new feeding system of the spiral channels ,as well as for

the matching ranges and the small die sets contributes to re-

duce pressure. This influences remarkably energy consump-

tion during extrusion considering that approximately 5 to

10% of the extruder power is necessary for the pumping ca-

pacity. Lower pressure also results in a lower increase of the

melt temperature and with lower residence times assuring

improved pipe’s characteristics with regard to OIT (oxidation

resistance) values, extra weight and thermal and sheer stres-

ses reduction.

VENUS MULTI die-heads can be endowed with two innova-

tive option units:

• the Pipe Air Cooling (PAC), - an efficient system to reduce

cooling length and improve pipe quality.

• the Venus Coex-Unit, - a radial spiral technology for addi-

tional (external) layer application.

sure losses and high flexibility in terms of layers structure

(thick or thin layers) and number of layers, while their short

flow path leads to reduced residence time and rapid material

and color changes. In a market, which is always more and

more looking for highly innovative development, with respect

to the growing improvement of material properties, single-

layer pipes are not always able to fulfil the necessary requi-

rements. Tecnomatic has well interpreted these customer

needs and has developed, on the basis of the VENUS con-

cept, a full range of die-heads for the production of 2, 3 or

4 layers polyolefin pipes even in big size. A project in

1.200 mm three layers, carried out in 2013, is the milestone

of the multilayer production made by Tecnomatic.