machines and makes them fit for use. They determine and

interpret data from their physical environment via sensors.

They are capable of gathering, digitalizing and wirelessly (at

least over a short distance) transferring data to a central pro-

cess computer and thus easily to the Internet. With the help

of so-called actors, they can influence physical processes in

their environment, prevent production down-times, minimize

material and energy consumption and help the operating

personnel with intervention and prevention. With this multi-

modal human-machine interfaces, production requires fewer

resources and is more energy efficient.

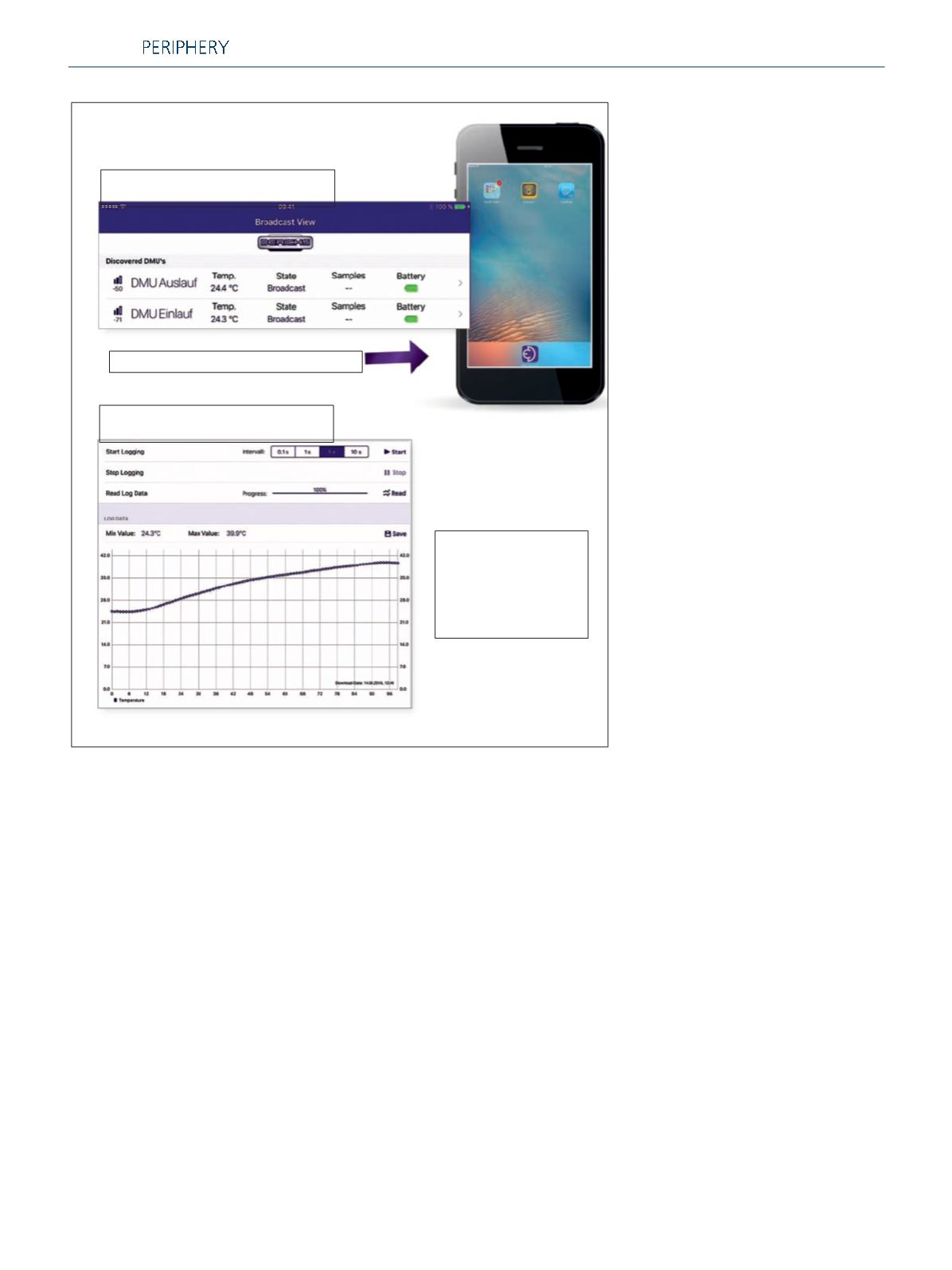

DERICHS ED1 – Temperature, pressure and flow rate control:

With the DERICHS ED1, Derichs is taking a huge step in ex-

actly this direction. This tool provides every roller with a digi-

tal memory. It can be retrofitted on any double-shell roller

and can data such as inlet and outlet temperature and input

and output pressure and the resulting profiles of each indivi-

dual roller can be displayed. Transferred wirelessly via wireless

radio to an app developed for Android or Apple systems, the

DERICH ED1 allows for direct and extremely precise monito-

ring of the actual values. This results in

new, additional options for the process

technicians to monitor and influence

the extrusion process. What is also in-

teresting for the machine manufactu-

rers is the possibility of directly

integrating the interface into the system

electronics. By means of regular, auto-

nomous screenings, the roller itself can

provide feedback if a significant change

in the internal conditions occurs. It is

therefore possible to intervene in the

overall process earlier and faster. In ad-

dition to optimizing the film, focus is

placed on the maintenance and re-

source conservation of the operating

medium and the roller. With respect to

further development, it is possible that

recommendations originating from the

roller regarding interventions in the on-

going process may be used in a variety

of ways for optimization. We can’t even

currently conceive the potential diversity

of options.

The development:

After initial feasibility studies by Profes-

sor Peter Gruber from the University of

Basel, the DERICHS ED1 was developed by the team sur-

rounding Professor Roland Keung in cooperation with the Zü-

rich University of Applied Sciences (ZHAW – Zürcher

Hochschule für angewandte Wissenschaft, School of Engi-

neering, ZSN) and has already been successfully tested on a

roller in a laboratory. Professor Roland Kueng from the Uni-

versity of Zürch is very convinced of the benefits for the cus-

tomers: “With this new Derichs development, the

temperature, for instance, can be precisely monitored during

production. First, because the measurement is taken directly

in the roller coolant and second, because the value is digi-

tally available to the heating controller as an actual value. If

the water temperature in the roller is reduced by 1%, this

saves 6% energy. If, for instance, there are greater deviati-

ons, an alarm can be triggered and the system can protect it-

self from being damaged.”

The facts:

The fact that the measurement values are digitalized directly

at the sensor by a measuring electronics system and a mi-

croprocessor offers the benefit that they are very precise and

The new innovation from Derichs:

the 1st electronic measuring tool for

monitoring the temperature, pressure

and flow rate in the roller

Permanent monitoring

Logging

Temperature curve

over a self-determined

logging period

...Control also via DERICHS App

Extrusion International 5/2016

36