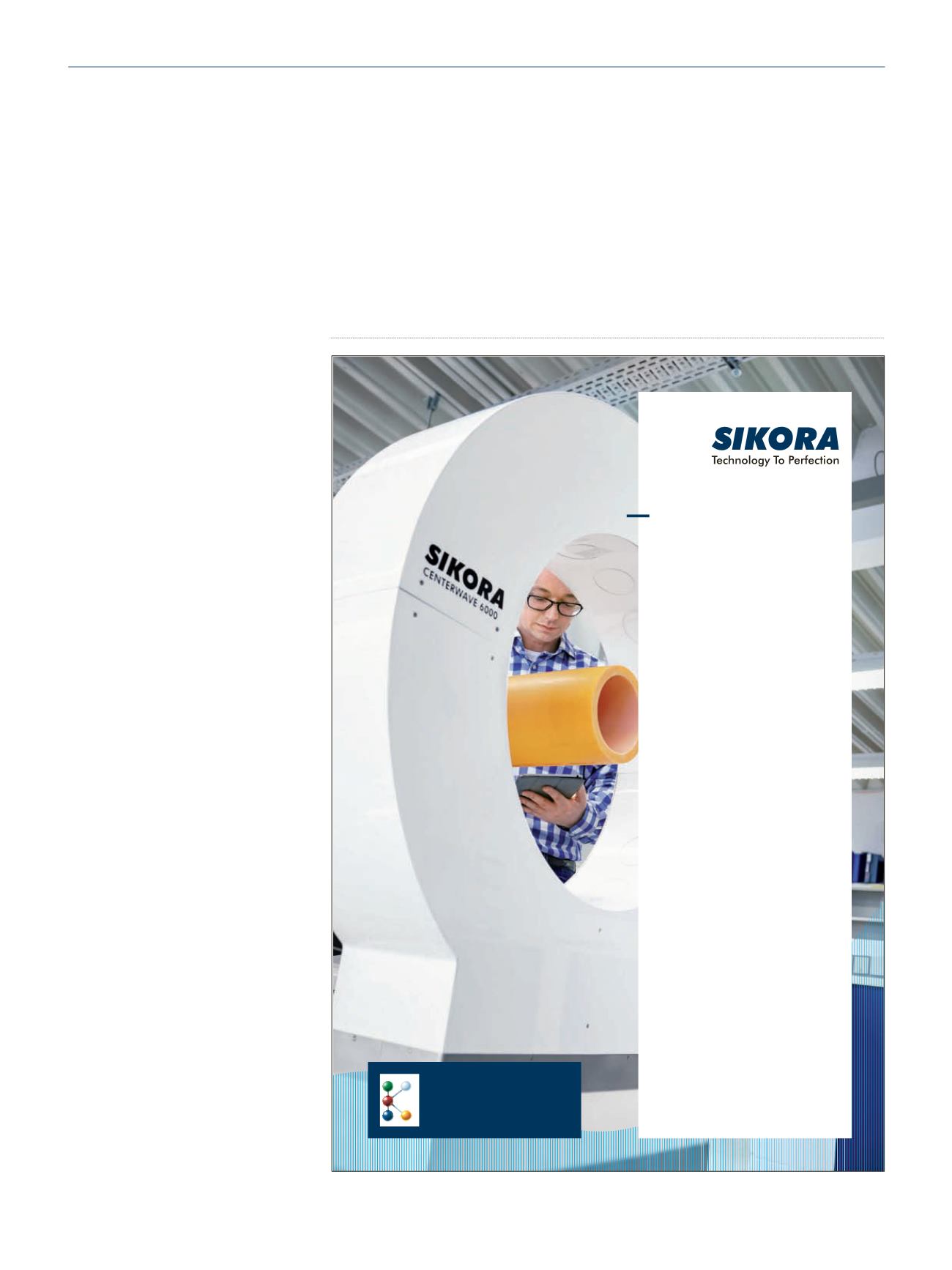

Quality in its

innovative

form.

With passion, we develop future-

oriented measuring and control

devices for quality assurance of

hoses and tubes, such as the

CENTERWAVE 6000

. A non-con-

tact system for the measurement

of diameter, ovality, wall thickness

and sagging of large plastic tubes

with a diameter from 120 to 2,500

mm. An innovative solution based

on millimeter wave technology

that increases product quality and

HQVXUHV VLJQLÀFDQW PDWHULDO DQG

cost savings during extrusion.

– easy operation without pre-

setting product parameters

– measurements independent from

material and temperature

– measuring results in real time

available for display and control

– reliable without calibration

www.sikora.net/centerwave6000Visit us from October 19-26

at the K 2016 in Düsseldorf,

Germany.

Hall 10, Booth H21

cannot be distorted during trans-

mission. The temperature sensors

delivery digital values with a preci-

sion of ± 0.5 degrees C, (upon re-

quest, als up to ± 0,1 degree C )

across a range of 100 degrees C.

“Derichs consciously selected a wi-

reless, digital date transmission me-

thod” explains Professor Kueng

“because the sensors are on the ro-

tating roller and cables in the vici-

nity of moving machine parts are

obstructive. It was important that

the data transmission be secure

and, upon request, encrypted and

that the radio protocol is standardi-

zed. The radio protocol meets the

Bluetooth 4.0 standard. Every mo-

dule has its own address so diffe-

rent sensors can clearly be assigned

to the measurement point and ma-

chine. Every five seconds, each mo-

dule is queried and these values can

also be tracked in live view mode

on an iPad tablet (Android in plan-

ning) or on a PC using a wireless

dongle.” The module can also log

values autonomously. The time in-

terval can be selected. The history

log files can be targetedly collected,

saved on the system side and eva-

luated, either manually or automa-

tically.. “It is a very valuable tool for

process engineers,” says Professor

Keung. "The module works in an

industrial temperature range of -40

to +85 degrees C. If thermally insu-

lated, the sensors can also be used

in rollers at up to 400 degrees C. “If

the process computer is connected

to the Intranet or Internet, this data

can be queried from anywhere.

“Thus Derichs has taken the first

big step toward the IoT: less waste,

less energy consumption, fewer

down-times.”

Passion for precision:

The name Derichs is known world-

wide for high-precision rollers in the

plastics industry and have always

stood for innovation and develop-

ment. With the Derichs ED1, the

new company management under

a female leadership (Maria Barthels

and Stephanie Holzmann) also pro-

➠ www.derichs-gmbh.deExtrusion International 5/2016

37

ves that it stands for quality and competence. Curious about the requirements of the

future, solution-oriented and innovative with respect to development, the DERICHS

ED1 is another milestone in the history of the plastics industry.

Right on time for the “K”:

This new development (including the shuttle) will be introduced for the K 2016 at an

exclusive in-house presentation on October 20th, at Derichs in Krefeld. Guest spea-

kers, including speakers from the ZHAW (Zürcher Hochschule für Angewandte Wis-

senschaft, School of Engineering, ZSN) will also be present.