21

Extrusion 7/2016

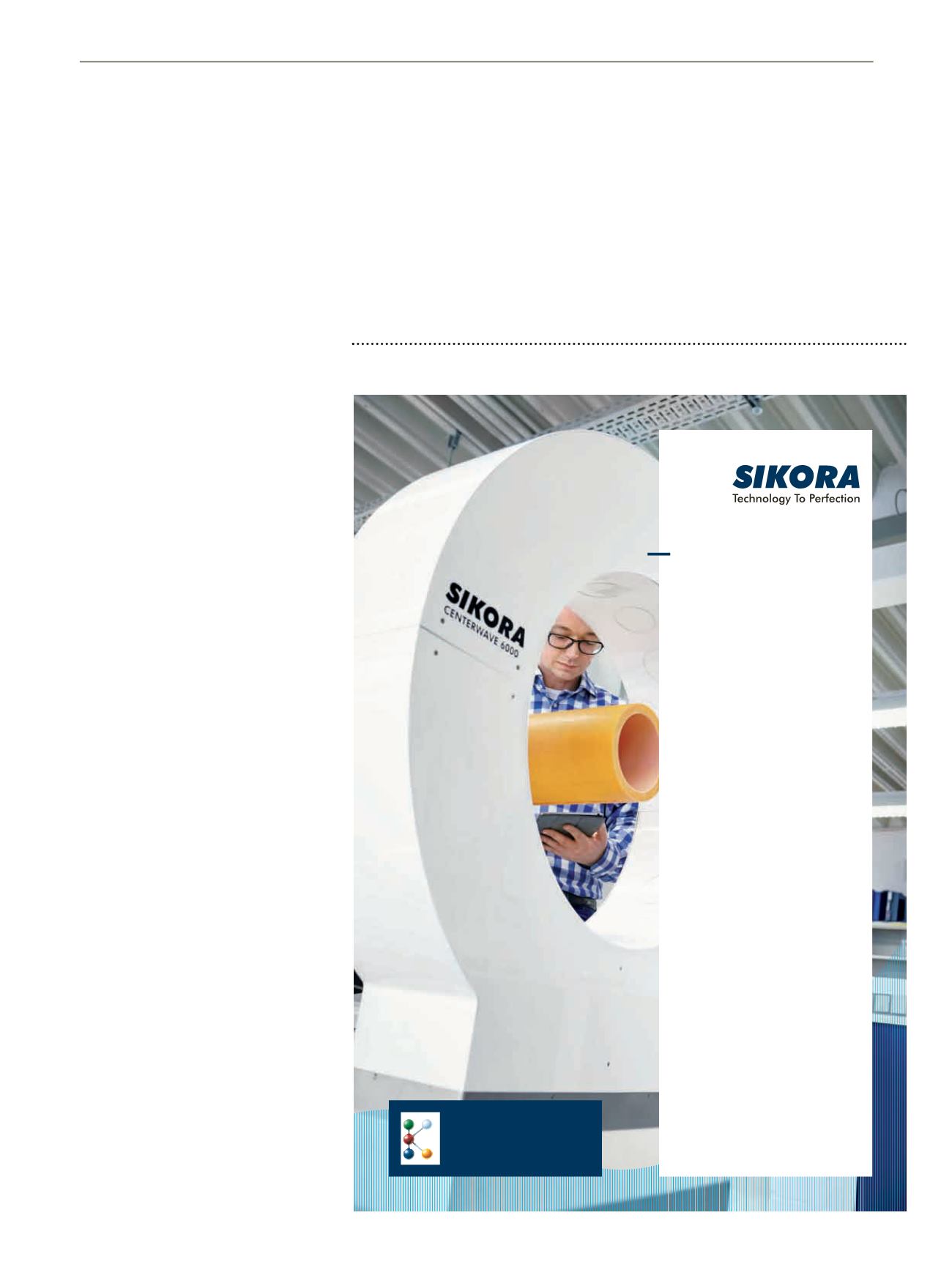

Quality in its

innovative

form.

With passion, we develop future-

oriented measuring and control

devices for quality assurance of

hoses and tubes, such as the

CENTERWAVE 6000

. A non-con-

tact system for the measurement

of diameter, ovality, wall thickness

and sagging of large plastic tubes

with a diameter from 120 to 2,500

mm. An innovative solution based

on millimeter wave technology

that increases product quality and

HQVXUHV VLJQLÀFDQW PDWHULDO DQG

cost savings during extrusion.

– easy operation without pre-

setting product parameters

– measurements independent from

material and temperature

– measuring results in real time

available for display and control

– reliable without calibration

www.sikora.net/centerwave6000Visit us from October 19-26

at the K 2016 in Düsseldorf,

Germany.

Hall 10, Booth H21

➠

Sukano AG

www.sukano.comK 2016: Halle 8a, Stand H28

sion flat film line from Dr. Collin. Both

machines will be installed at Sukano’s

global research and development center

in Switzerland. As a result, the company

will be able to produce multilayered films

as well as orient monoaxial and biaxial

films in-house for customers worldwide.

This unique offer from Sukano will dras-

n

Sukano, a world leader in the develop-

ment and production of additive and co-

lour masterbatches for polyester and

specialty resins, is launching its latest

matting agent additives masterbatches

for

biaxially-oriented

polyethylene

terephthalate (BOPET) flexible packaging

applications and polyethylene terephtha-

late (PET) rigid packaging bottles, enabl-

ing a total gloss control of the final de-

sired product appearance.

This broad portfolio of matting perfor-

mance masterbatches allows customers

to make packaging with sophisticated

look and feel available at affordable let

down ratios. By enabling total gloss con-

trol of the final desired product appea-

rance, designers are finally able to have

total creative freedom with regard to

gloss/matte control for packaging of

their end products, including high light

transmission.

Sukano’s new additions to its matting

agent masterbatch portfolio enable con-

verters to provide high-performance PET

bottles with a polyolefin-like low gloss vi-

sual look, while retaining all of the bene-

fit of the performance and features of

PET-based packaging.

For BOPET film applications, Sukano’s

experts have specifically developed a

new formula of matting agent to make

uncoated BOPET films appear very simi-

lar to coated flexible packaging, in terms

of visual aesthetics and low gloss effect.

This new innovative matting agent mas-

terbatch enables customers to finally

consider coating replacement.

As a world leader in the market for PET

and BOPET applications, Sukano is con-

tinuously looking for ways to improve

the look and feel of end products. “Our

innovations are the translation of brand

owner’s needs, reflected by consumer

preferences. Our latest matting agent

additive masterbatch is just one example

of our focused, agile reaction to market

needs, driven by our expertise”, explains

Alessandra Funcia, head of marketing.

Sukano is seeing very rapid and sustain-

able growth globally. In response to the

increased demand for its products and

services, significant investments are

being made this year, including the ins-

tallation of a Karo IV stretching machine

from Brückner and a multilayer coextru-

Total Gloss Control for PET Packaging with new Masterbatches

tically shorten development times and

speed up time to market for customers,

while reducing development costs.