41

Extrusion 7/2016

production of low-stress flat film, which is a special advantage

for the subsequent thermoforming process.

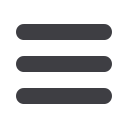

The calender the quality hub of a BREYER extrusion line

The BREYER fast&easy gap adjustment does without any me-

chanical control parts. A sophisticated system allows for the

precise positioning of the rollers during production and at full

load. Any required gap can be precisely adjusted. Speed, preci-

sion and operational comfort in one.

A maximum in flexibility

BREYER film calenders offer a maximum in flexibility for the

production. Easy operation with the push of a button: The set

values are entered via a touch screen color display.

Fast film thickness setting

In this system, the method of film thickness adjustment is uni-

que in extrusion technology. The gap adjustment has a mode

allowing the precise and automatic adjustment of the gap in

between the rollers just by changing the extrusion speed. The

operator changes the speed value appropriate for the new pro-

ducts on the display and has set the required thickness within a

few seconds. This represents clear savings in time and cost

compared with traditional gap adjustment, where the speed

has to be readjusted after the gap correction.

At the K-show Breyer will present the Key building blocks of the

entire line: Extruder 120, screenchanger, meltpump, die and

the calender.

Breyer GmbH Maschinenfabrik

Bohlinger Str. 27, 78224 Singen,

Germany

www.breyer-extr.com, www.breyer-thermoflex.comHall 16, Booth C18

ThermoFlex System

PET blister