ring molds, punches and stacking devices

that was specifically designed for the RV

53 is an essential component in the suc-

cess of this machine type. This enables the

customer to be able to construct his own

simple-design forming and punching tools

according to his own requirements and at

a very low cost. ILLIG's manual for mold

making that was designed specifically for

this machine type lets customers realize

the machine's full potential; ideal conditi-

ons for manufacturing formed parts eco-

nomically and efficiently, even for small

series production. It also offers the possi-

bility to have complete tool sets made by

Indian tool makers. ILLIG India offers its

customers and Indian tool makers support

for the technical realization of forming

tools. At the ILLIG India opening ceremony

two thermoforming tools made by Indian

suppliers were on display and demonstrated.

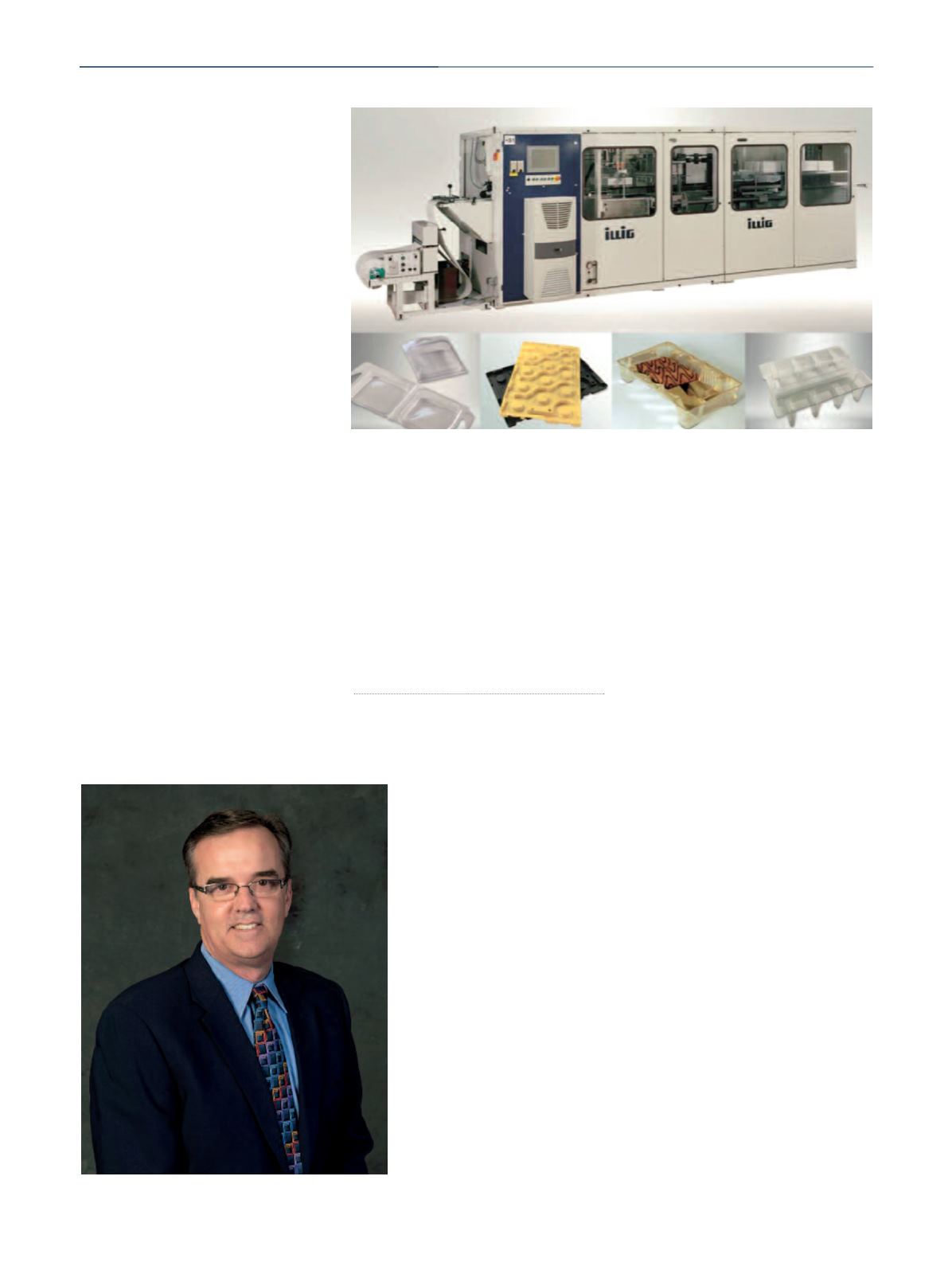

The ILLIG RV 53 is available in different models and different le-

vels of automation, and has a maximum forming area of 500

mm x 350 mm. Formed parts with a drawing depth of up to 100

mm above and 40 mm below the material level can be realized.

The RV 53 is capable of processing a wide range of materials in-

cluding PS, PVD and APET in material thicknesses from 180

µ

m

to 1.3 mm.

stranger to extrusion. Prior to starting Apex, he spent 35 years

in the decorative laminating industry, as the owner of a com-

www.illig.deNew General Manager for Extrusion and Coating dies

Extrusion International 1/2016

25

Nordson Corporation has promoted Ken Forden to be general manager

of the extrusion and coating die business within the company’s polymer pro-

cessing product line. Mr. Forden will have worldwide responsibility for the

EDI™, Verbruggen™, and Premier™ product brands. Andrei Stapinoiu, pre-

viously the global director of this business, has been promoted to the posi-

tion of managing director, Europe/Middle East/Africa, for the Nordson EFD

division.

Prior to taking on this new role, Ken Forden served as vice president and ge-

neral manager of Nordson EFD, a leading supplier of precision fluid dispen-

sing systems. He entered the polymer industry in 1987 as a business

development manager with Borg Warner Chemicals. Following the acquisi-

tion of Borg Warner Chemicals by General Electric in 1988, he spent 19 years

in management positions with GE Plastics. Subsequently he worked for six

years with Johns-Manville before joining Nordson EFD in 2012.

Mr. Forden holds an MBA from Vanderbilt University and a BSc degree in civil

engineering from Michigan Technological University.

pany that manufactured high-gloss sheet products for the au-

tomotive, marine, heavy truck and signage industries. His biggest

frustration was finding a vendor who consistently supplied high

quality extruded sheet, critical to sheet applications demanding

perfection. To fill that void, Buck founded Apex and took on his

former company as his largest client. He is steadily building his

client base and looks to add another Davis-Standard system in

the near future as production grows. Apex offers sheet in both

rolls and sheet and with custom color matching.

ILLIG RV 53 vacuum forming machine and typical applications

Ken Forden

www.nordson.com