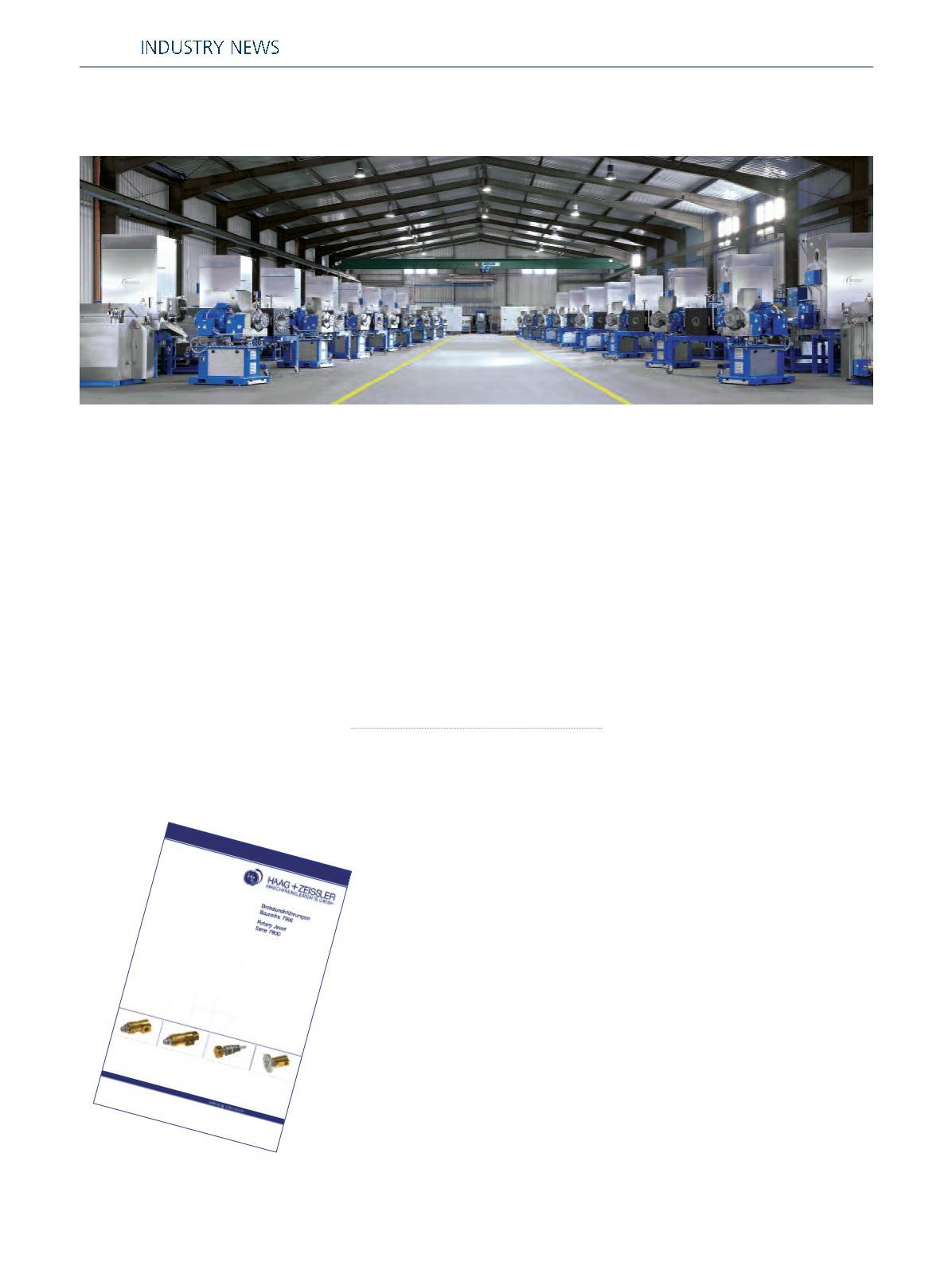

Nordson Corporation will supply sixteen of its process-pa-

tented BKG

®

brand CrystallCut

®

pelletizing systems for a mega-

scale PET resin plant scheduled for startup this year by Jiangyin

Chengold Packaging Materials Co., Ltd. in Jiangsu Province,

China. The big project reflects the intensified focus on pelletizing

systems for the Asian marketplace that will be evident in Nord-

son’s exhibit at Chinaplas 2016 (Stand W2-J01).

Nordson’s CrystallCut process provides substantial energy sa-

vings in comparison with standard PET polymerization systems

by using the thermal energy of the molten polymer in PET pel-

letizing for subsequent crystallization. In the Jiangyin Chengold

facility, the CrystallCut systems will deliver PET pellets to

EcoSphere™ solid state polycondensation (SSP) systems built by

Polymetrix AG, Oberbüren, Switzerland, which contracted for

CRYSTALLCUT

®

pelletizing systems in China

the use of the CrystallCut units. Chemtex Group, Wilmington,

NC, U.S.A. is the prime contractor for the entire bottle-grade

PET resin plant.

The CrystallCut system integrates underwater pelletizing, dry-

ing, water filtration and direct crystallizing at temperatures of

up to 180 °C and crystallinity up to 40%. In the new PET plant,

the system will provide a pellet temperature adjusted to the pro-

cess for crystallization and delivery to the SSP equipment, which

will be supplied by Polymetrix.

Nordson BKG will also supply sixteen condensation systems for

the water recovered from the hot air in the process, These are ex-

pected to provide substantial additional savings through reduc-

tion in water filling.

www.nordson.comThe tried

and tested ro-

tary joints from

the series 7900

by HAAG + ZEISS-

LER are now pre-

sented in a newly

published 12-page

brochure, which con-

tains general informa-

tion on the functional

principle as well as ope-

rating conditions and il-

lustrations, including the

dimensions of the indivi-

dual types.

The rotary joints from the se-

New brochure – series 7900 rotary joints from HAAG + ZEISSLER

www.haag-zeissler.comries 7900 enable water to be fed into rotating machine parts

and are characterised amongst other things by their small dia-

meter. This slender design allows the optimum integration of

the rotary joint even in cramped installation conditions or di-

rectly into the customer's shaft. A further special feature of the

series is the robust, vibration-proof CD-Cartridge-Design sealing

cartridge system. The rotor, the bearing and the stationary and

rotary parts of the seal are combined into a preassembled unit.

This quick-change cartridge system can be fitted with different

types of bearings and seal pairings and can be individually and

easily exchanged; machine downtimes are minimised. This se-

ries is available with a brass housing or entirely in stainless steel.

Areas of application are, for example, wire manufacturing, ex-

truders, mills, presses or shredders.

Extrusion International 1/2016

22