Extrusion International 1/2016

18

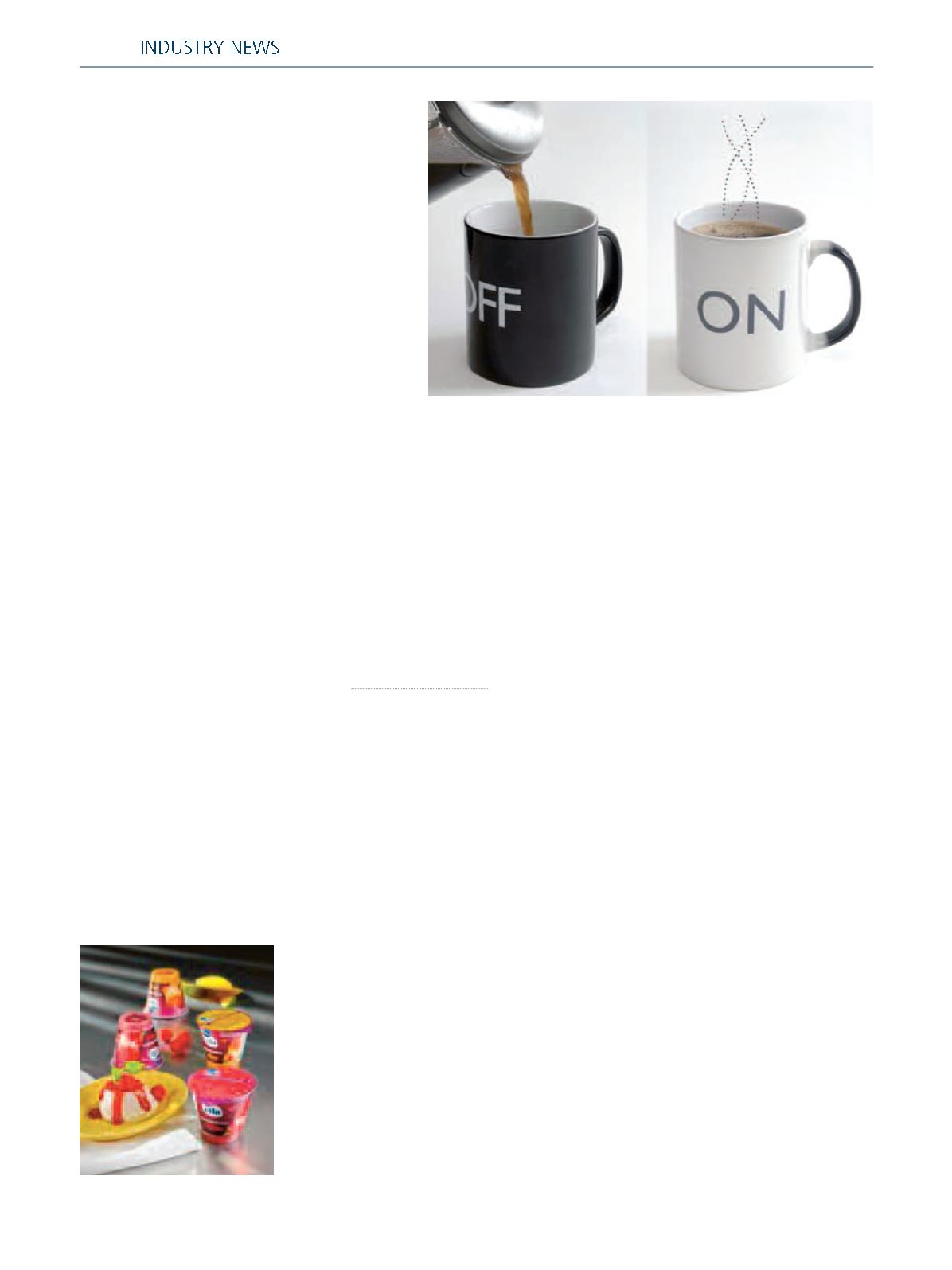

Thermochromic effects, i.e. temperature-dependent

color changes, are very important in the evaluation of

the color of plastic products. Since no basic research

has yet been conducted on this topic the German Pla-

stics Center SKZ is starting a project to investigate those

effects in detail.

Aside from base polymers, modern plastic compounds

consist of complex mix-tures of colorants and functio-

nal additives, which adjust the characteristics of the

material as required. Aside from the desired characte-

ristics, the combination of different substances also ge-

nerates unintended effects. These are particularly

unpleasant in terms of visual aspects due to the ex-

ceptionally high quality expectations prevailing in this

area.

However, thermochromic effects occur in inline and on-

line quality control of optical characteristics, which make quality

assurance considerably more difficult. For a better understan-

ding of these effects and to establish compensation measures

for quality assurance in the future, the SKZ is conducting basic

research on these topics.

The colored compounds used in the plastics industry are pro-

cessed at temperatures up to 300 °C. During the cooling, the

products display different but unam-biguous and specific color

behavior. The predictability of the color appearance of the final

products has to be enabled through investigating the thermally-

Hot and colored

www.skz.de(Picture source: Damianosullivan)

induced color changes. The superimposition of different effects,

such as crystallinity, thermochromism and the light scattering

behavior of further additives, is particularly challenging. By re-

searching these effects by means of scientific methods and the

transfer into application-oriented measurement devices, the pro-

ject, which is funded by the German Research Association (DFG)

becomes even more relevant.

The project “Investigating the thermochromic behavior of poly-

mers, colorants and resulting compounds” is funded by the DFG

under project number BA 1841/26-1. We would like to thank

for the financial support.

A bespoke dessert packing solution developed by RPC Su-

perfos for Finnish dairy producer Valio Ltd has been awarded a

WorldStar 2016, the pre-eminent international packaging

awards organised by the World Packaging Organisation (WPO).

The pack, for Valio’s lactose free dessert Valio Eila

®

cream pud-

ding with fruit sauce, features a special release mechanism that

makes it possible to serve the pudding and sauce on a plate wit-

hin seconds. The consumer only needs to take off the sealed

foil, turn the pot upside

down and squeeze the bot-

tom a few times. This makes

the pot break in three pla-

ces, and as the air enters,

the pudding and the fruit

sauce gently come out. The

result is a decorative instant

dessert on a plate and an en-

hanced consumer experi-

ence.

Juhana Pilkama, Packaging

Development Manager at

Bespoke dessert pack from RPC Superfos wins a worldstar

Valio Ltd. says: “We are absolutely delighted that our pack from

RPC Superfos has won a WorldStar Award 2016. It is the result

of a dedicated team effort and it is a moment of accomplish-

ment that everyone involved truly enjoys.”

The Valio Eila

®

cream pudding in the ready-to-serve dessert pack

has been a huge success. According to Valio Ltd, sales have ex-

ceeded expectations from the beginning.

“It is crucial to be innovative and to serve our customers in the

best possible way,” comments Per Sollenby, Sales Director Food,

RPC Superfos Region Nordic. “The award shows that we are up

to the challenge and that the RPC Superfos packaging solution

is an example of international packaging excellence. We are all

very proud.”

Judging for the WorldStars took place in October 2015 in Mum-

bai, India, when representatives from 17 packaging associati-

ons, all members of WPO, judged 293 packaging projects from

35

countries.Towin a WorldStar award, a pack must have won

a national or multi-national competition, recognised by WPO. In

autumn 2015, RPC Superfos’ bespoke dessert pack was honou-

red with a Scanstar in the Nordic packaging competition.

www.rpc-superfos.com