Online and offline analysis of

Pellets and Flakes

One concept - several possibilities to assure quality

E

specially interesting are the systems for the manufacture

of medical hoses. An essential criterion for hoses of the

medical field is the absolute purity of all materials in order to

ensure highest quality for the demanding range of applica-

tion.

Incoming goods inspection

Sensitive end products require a similar reliable control and

processing of the raw materials. The transport of the plastic

pellets, which are usually transported in large tanker lorries

and stored in a silo at the plant, shows some weak points for

contamination. For example, the discharge from the trans-

port vehicle to the silo offers potential contamination from

dust or other impurities a way. Until now, only samples have

been checked manually before the material was processed.

But even with the utmost care there might be contamina-

tion, which cannot be seen by the human eye – metallic and

organic contamination inside the pellets/flakes from 50 µm.

Therefore, SIKORA recommends the usage of a PURITY CON-

CEPT System device for the inspection and analysis with

SIKORA presents its new and pioneering models

of the PURITY CONCEPT Systems. With that, the

company offers an outlook on the varied

potential of its systems for online and offline

inspection and analysis of plastic material.

According to the application, the systems are

equipped with X-ray technology (X), infrared

technology (IR) or optical sensors (V) and can be

used for samples during the production in order

to find impurities from 50 µm.

www.sikora.netoptical sensors for transparent pellets/flakes and X-ray tech-

nology for black pellets/flakes for instance. This is the only

way for incoming goods inspections to ensure that the raw

material already has the desired quality needed for the end

product.

Online measurement up to 50 kg throughput

During the processing of high-quality and therefore high-pri-

ced XLPE materials it is often not enough to rely only on sam-

ple tests. Here it is useful to integrate an online analysis in the

production process. For a low throughput up to 50 kg per

hour, which is common during the extrusion of medical hoses

for example, SIKORA offers the PURITY CONCEPT System

with conveyor belt that can easily be integrated in existing

lines. Depending on the model, the device inspects pellets

and flakes with optical sensors or by using X-ray technology

for contamination from 50 µm before the material enters the

extruder.

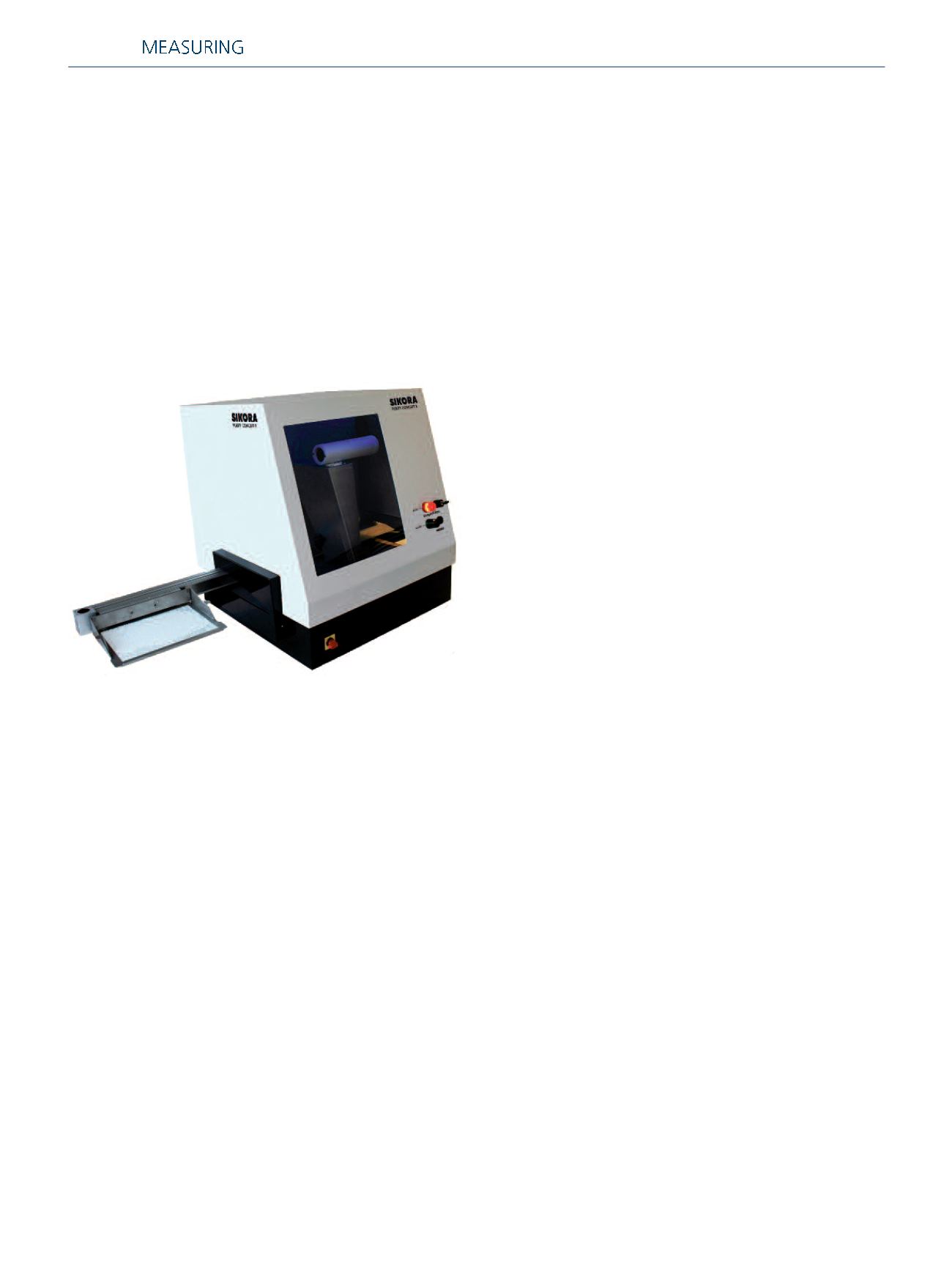

SIKORA PURITY CONCEPT X for sample analysis (Image: Sikora)

Extrusion International 1/2016

42