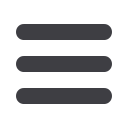

Extrusion Plant

for Thermal Break Profiles

T

he plant ensures the production of 8 profiles at 2mt/min

(90 kg/h) and it is composed of a single-screw extruder

Omega80 with PLC, in which the raw material arrives already

dried, and classical downstream with insertion of auxiliary ma-

chines. A gear pump helps the process stability but the mate-

rial flow is constant and homogeneous, despite the complexity

of the 8 strands, thanks to the special technology Friul Filiere

applied to the die. In fact there is not even any need for a

chiller. The control of the 8 strands is assured by a dedicated

calibration system with die-calibrator centering which allows a

perfect alignment and facilitates the positioning of the pro-

files. The flexibility of the extrusion plant has allowed the in-

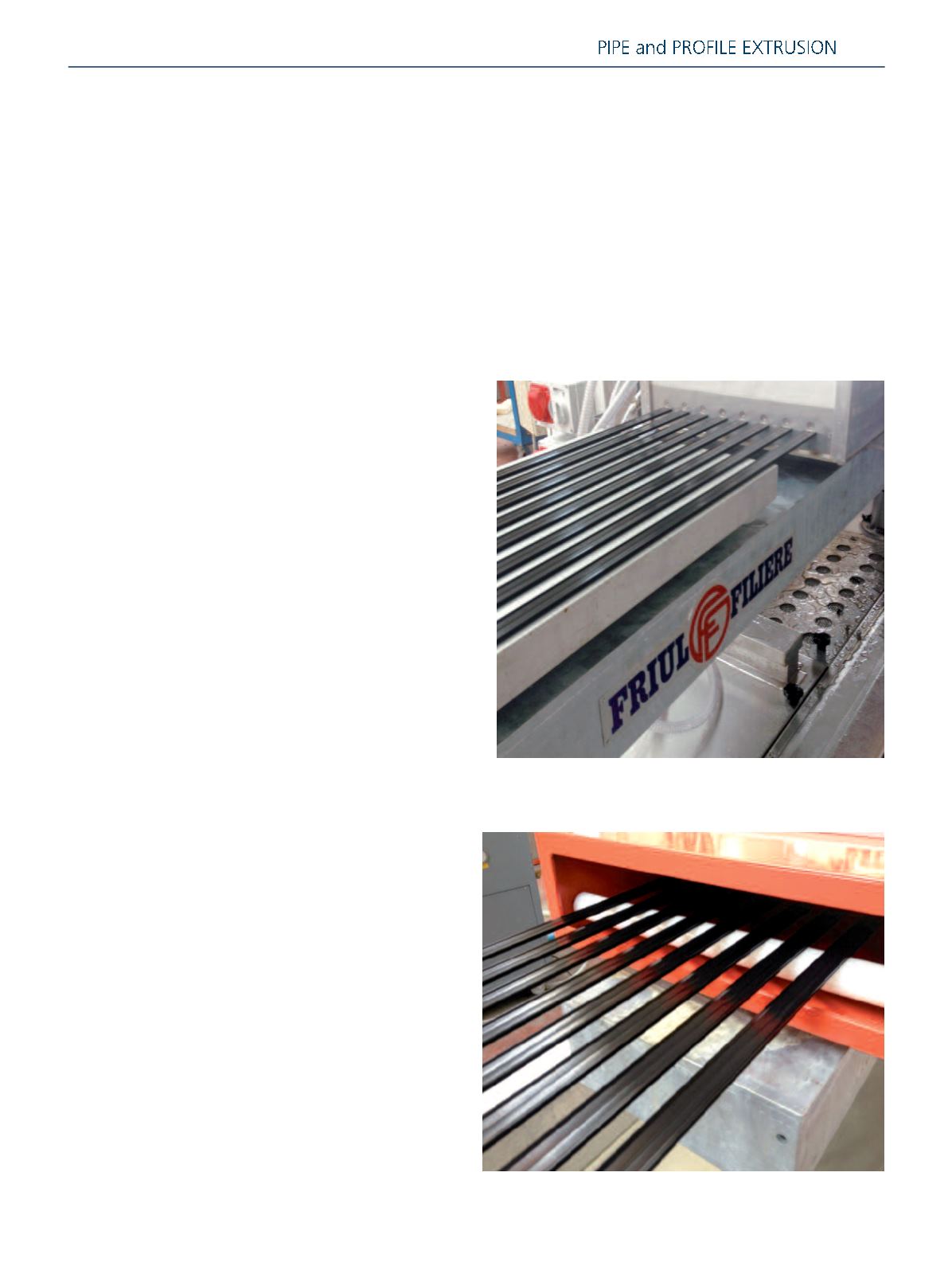

sertion in line of a sandblasting unit and a glue insertion

system. The sandblasting unit prepares the profile surface that

will be varnished together with the window frame, allowing a

better accession of the varnish. The glue insertion system fa-

cilitates the assembly.The extruded thermal break profile pres-

ents mechanical characteristics of resistance similar to

aluminum but ensures high thermal insulation performance.

www.friulfiliere.itExtrusion International 3/2016

21

Friul Filiere SpA has realized for a European

customer a complete plant for the extrusion of

thermal break profiles in 8 strands. An excellent

result considering the particular characteristics of

this material. PA66 is a nylon with very high

processing temperatures which entail calibration

difficulties. Furthermore, the reduced tolerances

(in the order of hundredths) which requires their

application within windows and the production

of 8 profiles simultaneously, further complicate

the extrusion process.

Thermal break profile