Extrusion International 3/2016

23

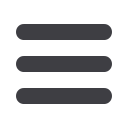

www.kraussmaffeiberstorff.comTwin-strand technology –produced

locally with German engineering –

to reduce unit wage costs

"Economical production, high outputs

and perfect end product quality have

also long been standard requirements

in the mechanical engineering and sy-

stem construction industry in China,"

emphasized Michael Hofhus, Vice Pre-

sident Extrusion at KraussMaffei Ber-

storff in China. "As a competent system

supplier, we have been satisfying preci-

sely these needs of our customers

through our product portfolio in the

Performance Series from our plant in

Haiyan for several years. On a highly

competitive local market processors

focus on both quality and lower unit

wage costs," said Hofhus. The twin-

strandline, which will produce PP-R

pipes live from 12.00 to 13.30, will de-

monstrate very clearly how economical

production functions in a confined

space. The line will produce PP-R pipes

with a diameter between 20 and 40

mm at a speed of up to 25 m/min per

strand and an axial distance of 450 mm.

The core components of the line are the

single-screw extruder KME 75-30 B/R,

two co-extruders KME 20-25 D/C for

strip production and two pipe heads

KM-RKW 32 from the locally produced

Performance Series. The line is comple-

ted by other components ranging from

a suction conveyor, a cooling zone, a

saw and a haul-off through to a drop

off table. The C6 line control system en-

sures optimum monitoring and safe

process control.

Expansion of the market position thanks

to the successful Performance Series

"In the last few years we have placed

complete lines up to a diameter of 1200

mm on the market. However, we are

not only very successful as a system

supplier for complete lines, but also in

business with individual machines,"

added Hofhus. "With our single-screw

extruder model KME 60-30 B/R from

the Performance Series, we offer pro-

cessors a suitable machine concept,

especially in regard to locally used ma-

terials," said Hofhus.

The 30D Series, an extension of the sin-

gle-screw seri es that has been used

successfully for many years, is perfectly

designed to process local PP-R material

thanks to its revised screw concept.

"The advantage here is the short pro-

cessing unit which ensures optimum

thermal and material melt homogeneity

with high output, and therefore a final

product of the highest possible quality.

KraussMaffei Berstorff

twin-strand

extrusion line

for production

of PP-R pipes

www.illig.deAnother important criterion for Chinese

producers who are increasingly setting

themselves apart from competitors on

the local market through high -quality

products," said Hofhus. The exhibit in

the 30D Series, which is produced at

the production plant in Haiyan, is equip-

ped with the new user-friendly C6 con-

trol system with its modern operating

philosophy.