delivery) or “energy monitor”

Film producers will find it easier to produce the highest film

quality all over the world, independent of surroundings, time,

climate and weather conditions.

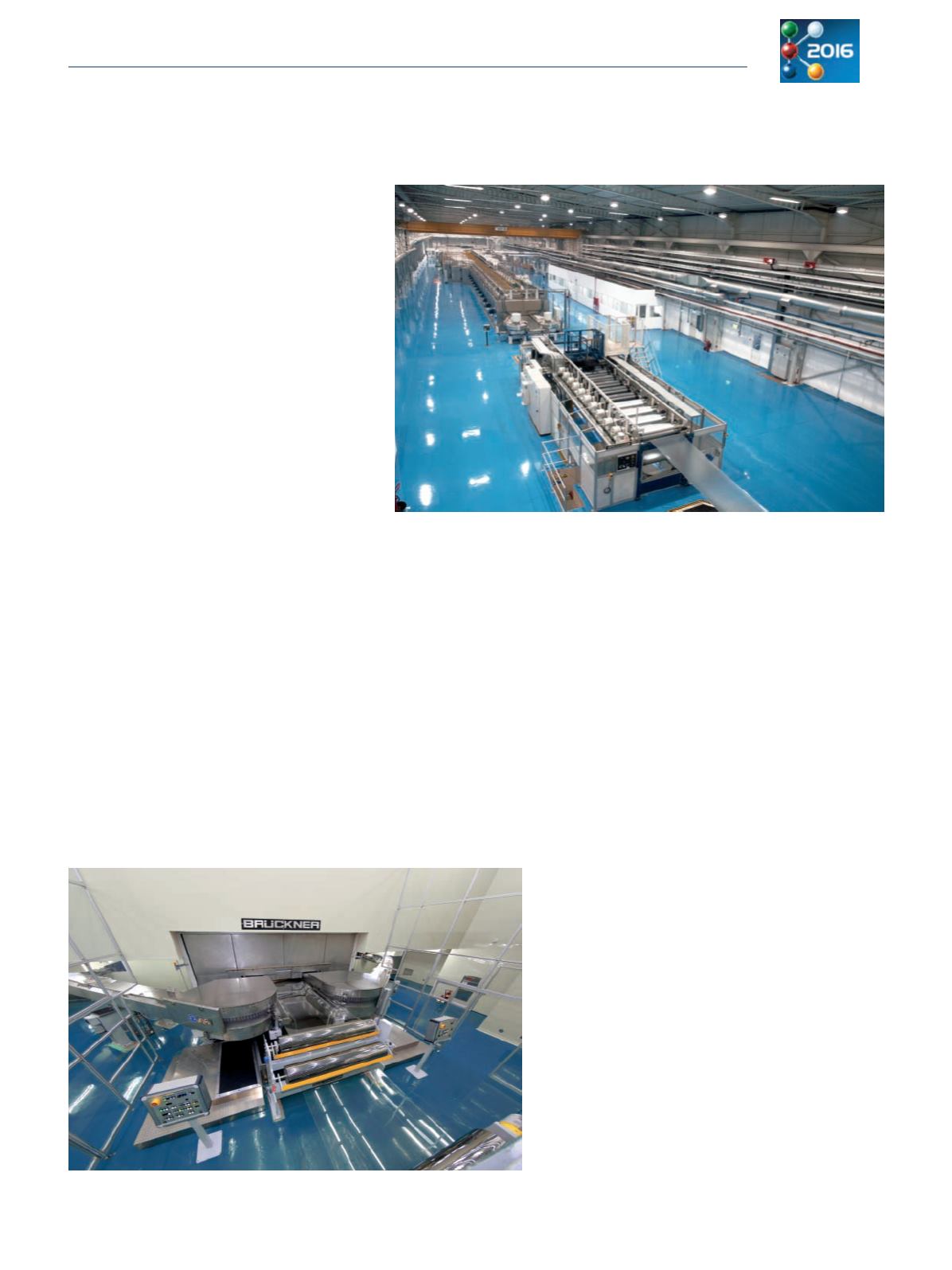

BOPET lines with 10.4m working widths

Nowadays the established working width for lines that pro-

duce biaxially stretched polyester packaging film (BOPET) is

8.7m. For the K 2016 Brückner Maschinenbau will present a

10.4m concept for the first time ever in the world. This will

fulfil the demands for higher productivity in BOPET produc-

tion: The new lines convince with around 20% more output

capacity with the proven speeds of up to 515m/min. Film pro-

ducers can hereby profit from Brückner Maschinenbau’s ex-

perience from many successful projects with over 10m

working widths, from fewer specific production costs as well

as reduced energy consumption and therefore better

overall profitability.

Lower operating costs with higher efficiency

Brückner’s newly designed sliding system for trans-

versely stretched film means speed increases from over

600m/min. At the same time newly developed mate-

rials led to a reduction of the lubrication use by more

than 50%. The new design in combination with newly

developed lubrication is the basis for lower production

costs. Furthermore these newly developed lubrication

materials are also available for upgrades on current

high-performance lines.

A new winder system caters for higher line efficiency.

In the future Brückner lines can take 40% more win-

der length by increasing the winder diameter from

1.55m to 1.8m. More winder length means fewer roll

Brückner:

improving the efficiency of film lines

Intelligent Line Management

Continually increasing speed and output with

ever shorter delivery times and growing demand

for quality make running a film stretching line a

highly complex business. Film producers and

their operating personnel stand before increa-

sing challenges when it comes to guaranteeing

a stable and efficient production with the hig-

hest quality film.

This is where Brückner’s “Intelligent Line Ma-

nagement” (ILM) comes in. This is an integrated

solution which smooths the way for Brückner’s

customers’ “Smart Production” and “Industry

4.0”. The focus lies here on a new way of ope-

rating lines, putting the emphasis on the process

view as opposed to the usual machine view. This

new operating concept is supported by an in-

creasing amount of assistant systems.

Along with the “Energy Monitor” which is al-

ready used to monitor energy consumption at all line compo-

nents, Brückner has developed new tools and assistant systems

for inline measurements and to directly influence important

film values such as temperature, haze, molecular orienteering

angle or also density and porosity. For film production this

brings a variety of advantages:

• Simplified line operation with significantly fewer process pa-

rameters to adjust and intuitive user guidance

• Transparency and traceability of production data

• Targeted inline control of film properties for a consistently

high film quality

• Increased line availability through shorter reaction time in

case of malfunctions

• Efficiency, productivity and flexibility through assistant sy-

stems such as “fast product change” (key word: Just-in-time-

Extrusion International 5/2016

51