NEW: Step Dryer of the HV ST-150/150 Series

(Exhibit at the Trade Fair)

The vertical step dryer consists of a multiple-stage rotor de-

watering the material via a screen basket. The granules/grin-

ding material water mass enter the machine from the bottom

and are transported upwards by conveying blades. The dia-

meter of the rotor increases upwards following the single

steps. In the lower area (where free water can still be separa-

ted easily) only inferior circumferential speeds occur, at the hig-

hest step, drying is done with maximum circumferential speed.

The step dryer is

ideal for drying

grinding material

or granules of all

different types of

t h e r mo p l a s t s

such as polycar-

bonate, polyethy-

lene, polyamide,

po l yp ropy l ene

and polystyrene.

This machine is

particularly suit-

able for drying

brittle

plastics

and guaranteeing

at the same time

the least possible material loss caused by fines. The step dryer

yields a residual humidity in the range between 0.4 and

0.06%/weight. The machine is also available in a gas-proof

execution for drying in an inert atmosphere.

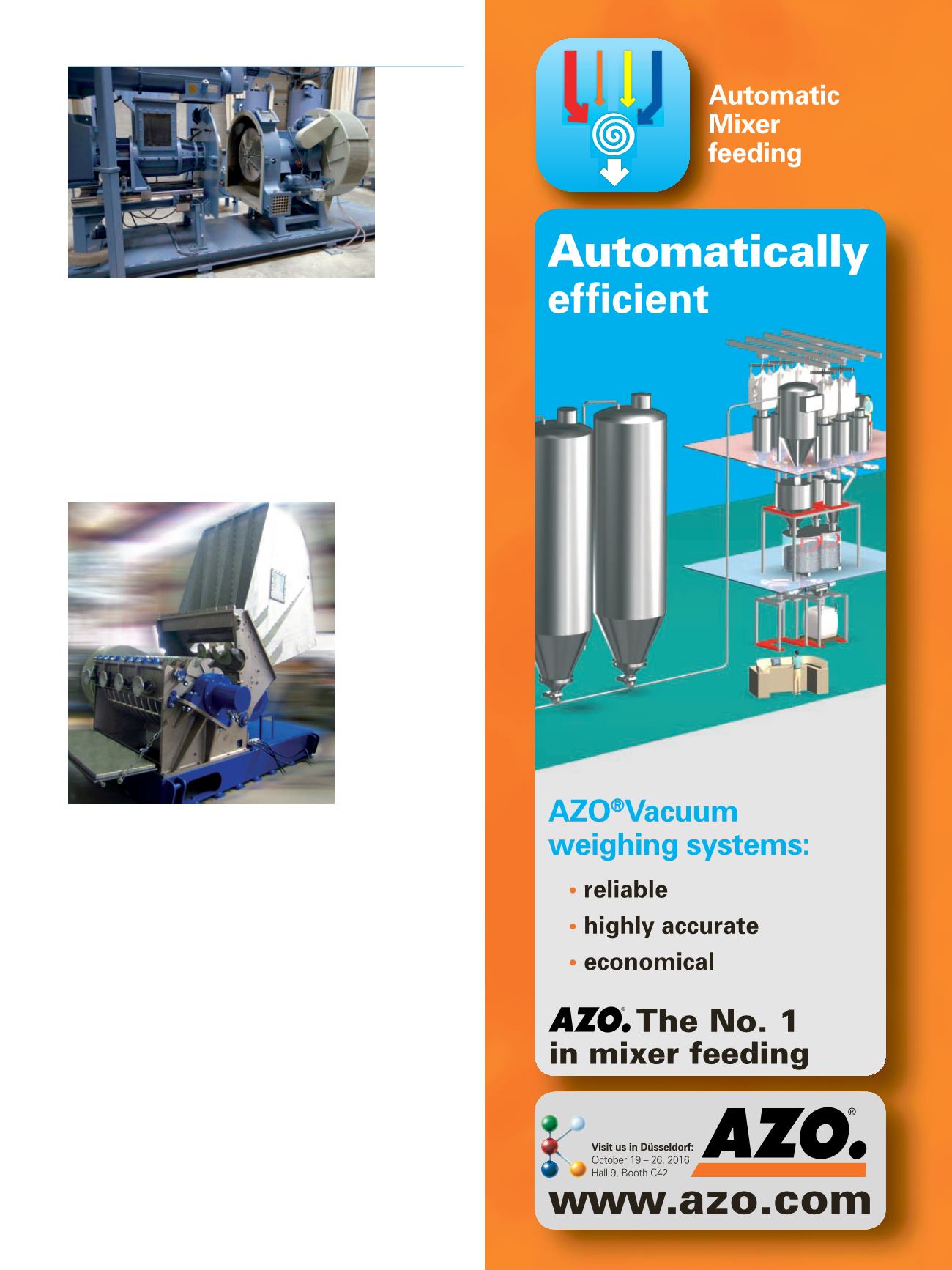

Agglomerating / Densifying

With extreme materials such as stretch film or foams, a suffi-

cient mechanical or thermal drying is not possible without high

energy consumption. The solution to this problem is the Her-

bold Plastcompactor, a modern compacting machine. The fric-

tion originating between the compacting discs of the

compactor heats, dries and compacts the material at the same

time. The recycling of PET bottles has a double advantage: the

material is being crystallized at the same time. The end product

is agglomerated material with excellent flow properties and a

high bulk density, ideal for dosing and mixing.

Herbold

Granulators SB

with forced

feeding

Herbold

Plast-

compactor

HV 70 Series

Hall 9, Booth B42

➠ www.herbold.comExtrusion International 5/2016