ProTec Polymer Processing:

efficient materials

handling of LFT compounds

W

ith the high-performance, energy-efficient plant and sy-

stems for pre-processing flowable plastics presented at

K 2016, ProTec Polymer Processing now covers the entire pro-

cess chain from conveying and drying to metering and mixing

whether

for injection moulding or for extrusion. A second focus of Pro-

Tec's presence is its abilities as a one-stop shop supplier of

long-fibre-reinforced thermoplastics (LFT) lines covering the

full gamut from planning via construction to commissioning.

New developments presented for the first time at K 2016 in-

clude the SOMOS

®

Batchmix XL batch metering unit for

throughputs of up to 1,920 kg/h and the stationary SOMOS

®

RDT-200 dry air dryer for moderate throughputs.

The SOMOS

®

Batchmix XL metering and mixing system is suit-

able for feeding multicomponent mixtures to both injection

moulding machines and extruders and is designed to handle

up to six flowable components. It can be equipped with

SOMOS

®

suction conveyors for automatically filling material

storage hoppers. A SOMOS

®

control/professional touchscreen

controller with a graphical user interface ensures user-friendly

operation and is also capable of simultaneously controlling ex-

truder throughput. The Batchmix M for throughputs of up to

240 kg/h and the Batchmix L for throughputs of up to 1,100

kg/h of a homogeneous multicomponent mixture complete

this range of gravimetric batch dispensing systems. The new

SOMOS

®

Batchmix unit offers high metering accuracy at an

attractive price/performance ratio.

The new SOMOS

®

RDT-200 stationary dry air dryer has an ef-

fective dry air throughput of 140 to 300 m³/h, enabling highly

economical processing of material volumes in excess of the

throughput capacity of the SOMOS

®

RDM mobile auxiliary dry-

ers (dry air throughput of at most 140 m³/h). The dry air ge-

nerator and the drying vessel are also of a new design. The

drying vessels, which are square on the outside and cylindrical

on the inside, can be fitted together to form a compact mo-

dular drying system comprising up to at most six vessels in gra-

duated sizes with effective hopper volumes ranging from 50 l

to 300 l. Another new feature is the SOMOS

®

control excel-

lence dryer controller with its user-friendly touchscreen ope-

ration which offers numerous drying parameters tailored to

the specific material as well as versatile documentation functi-

ons. To minimise energy consumption, the dryer is equipped

with the tried and trusted energy-saving technology known

from SOMOS

®

dryers: automatic adaptation of drying air vo-

lume to material throughput (ALAV) and the SUPER SOMOS

control mechanism which adapts desiccant regeneration to

the particular moisture loading of the adsorbent. Drying tem-

peratures of 40 °C to 180 °C at a drying air dew point tem-

perature of approx. -35 °C are standard.

The new SOMOS

®

Batchmix XL gravimetric batch metering unit is

designed for a maximum of six components and throughputs of up

to 1,920 kg/h

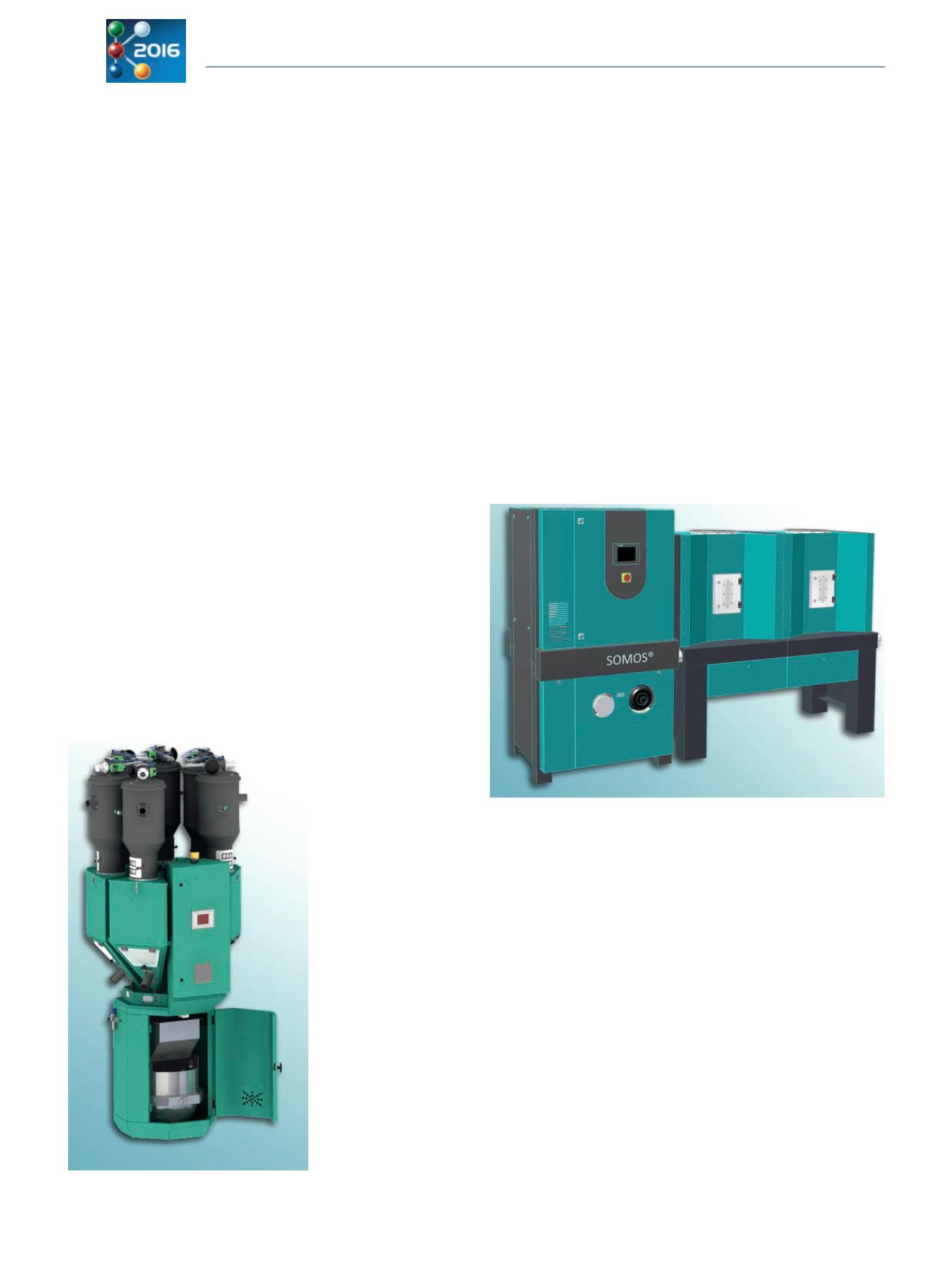

The new SOMOS

®

RDT-200 stationary dry air dryer with its new

design can provide a variable dry air throughput of

140 to 300 m³/h for economically processing

moderate material throughputs

Extrusion International 5/2016

54