blow-mould materials made from HDPE and PP in single- and

multi-layer designs (3-layer and 6-layer), including those with

transparent strips and polycarbonate, can be processed with

excellent results. The new design allows very fast colour

changes for the highest level of flexibility and cost efficiency.

Through the use of a characteristic BEKUM top or bottom

calibration, the production range can be expanded even furt-

her. Many proven and processsafe options of the familiar BA

34.2 will also be available in the new EBLOW 37. The future

is electric – including in the packaging.

Hall 14, Booth C03

➠ www.bekum.deAMUT:

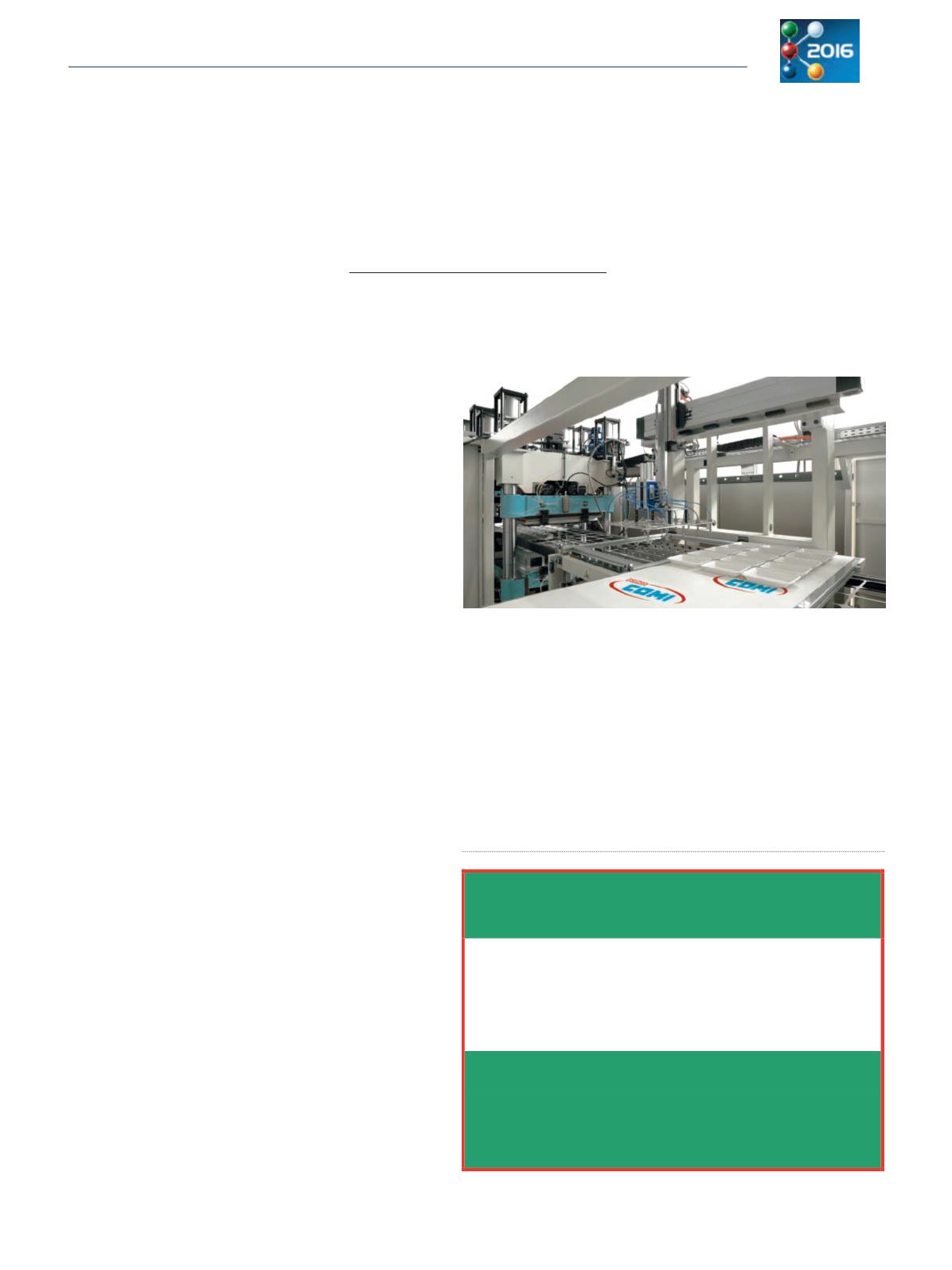

ACF 820 series of steel

rule cutting machines

T

he ACF 820 machine combines the characteristics of

V and F series, thus creating an innovative model ha-

ving:

- high level of standardization,

- exceptional repeatability,

- rugged durability,

- flexible production for a wide range of articles,

- increased high-speed performances.

This range of machines is suitable to handle different ma-

terials, such as PET, APET, RPET, CPET, OPS, HIPS, PS, EPS,

PP, PLA, PVC and to produce many items: trays, lids, fruits

and vegetables boxes, flowerpots, clamshells, nursery

trays and plates.

The ACF series has a modular concept and can be sup-

plied in different configurations such as:

- forming;

- forming and cutting in the same station;

- forming and cutting in two stations;

- forming, punching and cutting in three stations.

Up or down stackers, three-axis robot as well as custo-

mized special solutions are available to stack thermofor-

med parts with different nesting requirements.

To fulfill all thermoformers requirements and to meet any

potential demands, the ACF 820 can be equipped with a

wide range of options, including: servo driven plug assist

on upper and lower mould platens, high performance

mould clamping and cutting force, quick tools change

devices, different heat ovens configuration with power

saving heaters and many others.

The forming and cutting presses are equipped with coun-

terbalanced platens to increase the machine perfor-

mances at high speed. This series of machines is

completely servo driven and equipped with a new soft-

ware for cycles control that, along with a HMI friendly

use, guides the operator through the settings pages pro-

viding full diagnostic analysis.

The ACF machines can be integrated with a T-IML system

(In-Mould Labelling for the thermoforming sector), based

Hall 3, Booth E40

➠ www.amut.itExtrusion International 5/2016

59

PLASTICO TRADING

6XSSOLHU RI SODVWLF SURFHVVLQJ PDFKLQHV

*

UDQXODWLQJ

&

RPSRXQGLQJ

5

HF\FOLQJ

/

LQHV

6

LQJOH DQG

7

ZLQ

6

FUHZ

(

[WUXGHUV

$

FFHVVRULHV

*

ULQGHUV

6

KUHGGHUV

3

HOOHWL]HUV

*

UDQXODWRUV

,

QMHFWLRQ

0

RXOGLQJ

6

HUYLFH

&

RPSOHWH

/

LQHV

8

VHG DQG

1

HZ

0

DFKLQHV

%X\LQJ DQG 6HOOLQJ ± FRQWDFW XV

near Airport & K-Show 2016 Düsseldorf

3/$67,&2 75$',1* *PE+ &R .*

9RKZLQNHOHU 6WU

Ɣ '

:XSSHUWDO *HUPDQ\

7HO

±

Ɣ )D[

±

(PDLO VHUYLFH#SODVWLFRWUDGLQJ GH

KWWS ZZZ SODVWLFRWUDGLQJ GH

on a side entry robot to load labels inside the forming mould in

order to decorate the articles.

The use of steel rule cutting moulds makes this T-IML even more

competitive compared to the existing TIML systems based on

punch and die mould and to injection molding technology.