S

ince the beginnings of the "K"trade show in the 1950s,

the Institute of Plastics Processing (IKV) in Industry and the

Skilled Crafts at RWTH Aachen University has been high-

lighting selected research topics on this international platform.

At K 2016, IKV will be presenting the topics additive manu-

facturing and integrative production technology in the form

of a Cyber Physical Production System (CPPS) – in short: Indu-

stry 4.0 – for plastics processing.

In its research projects in the field of additive manufacturing,

IKV takes a multi-material approach that covers a range of dif-

ferent products. On the one hand, it performs fundamental

analyses to examine the influence of the processing process

on the properties of plastics products. On the other, it looks at

the potential of using additively manufactured metal mould

elements in the various plastics processing processes. Along-

IKV:

focus on Industry 4.0

and Additive Manufacturing

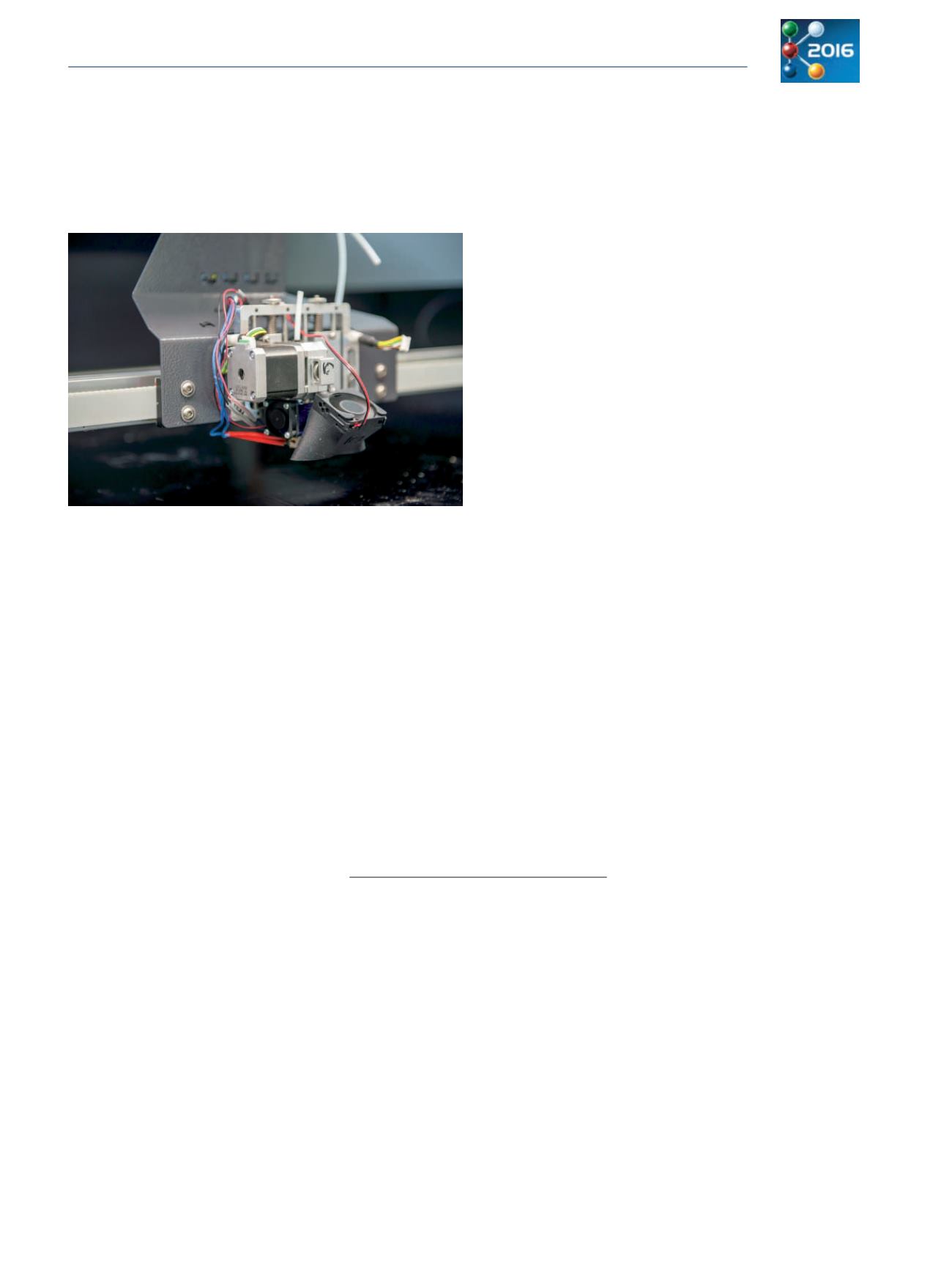

Print head of the X1000 3D printer from German RepRap

in the IKV pilot plant for additive manufacturing

(photo: IKV/Fröls)

side the practical analysis of different additive manufacturing

processes, the focus is above all on the physically motivated

numerical modelling. This holistic research approach by IKV

aims to create a fundamental understanding of the process.

In addition to already established processes such as Arburg

Plastic Freeforming (APF) and the Fused Deposition Modelling

(FDM) process from German RepRap GmbH, IKV is also buil-

ding expertise and competence of its own via its own machine

developments, and is overcoming existing limitations by lin-

king up various pieces of machinery. The aim is hybrid pro-

duction for the automated combination of different

production processes. In a production cell, the Institute will

show not only the automated fine machining of additively ma-

nufactured parts, but also various insert operations and the in-

tegration of further production steps.

On the subject of Industry 4.0, IKV will, in cooperation with a

strong industry consortium, address the subject of the appli-

cation-specific manufacture of function-integrated lightweight

parts. On the IKV stand, the Institute will present, up and run-

ning, a fully automated production cell based on an injection

moulding machine. The versatility and flexibility of the process

will be demonstrated through ergonomic interaction with the

visitor.

Hall 14 Booth C16

➠ www.ikv-aachen.deDESMA:

the standards for a new industrial AGE

A

t the K 2016, the Fridingen-based mechanical enginee-

ring company presents itself stronger than ever with

around 75% of additional exhibition space compared to the

years before: Besides two DESMA injection moulding machi-

nes of the S3 series with robot integration and the newly de-

veloped e-drive cold runner system, DESMA also showcases

its platform for digital solutions, the product range of Smart-

Connect 4.U which intelligently networks machines, compo-

nents, applications and systems and thus provides its customer

partners with further possibilities of increasing competitive-

ness.

Focus set on automation

. On booth 16F56, DESMA exhibits

two injection moulding machines of the S3 series each equip-

ped with a production cell with robot system. The machines

can easily be switched over from machine operation to system

operation and thus are ready for flexible use. On the one hand

it is possible that one individual operates several machines, on

Extrusion International 5/2016

75