I

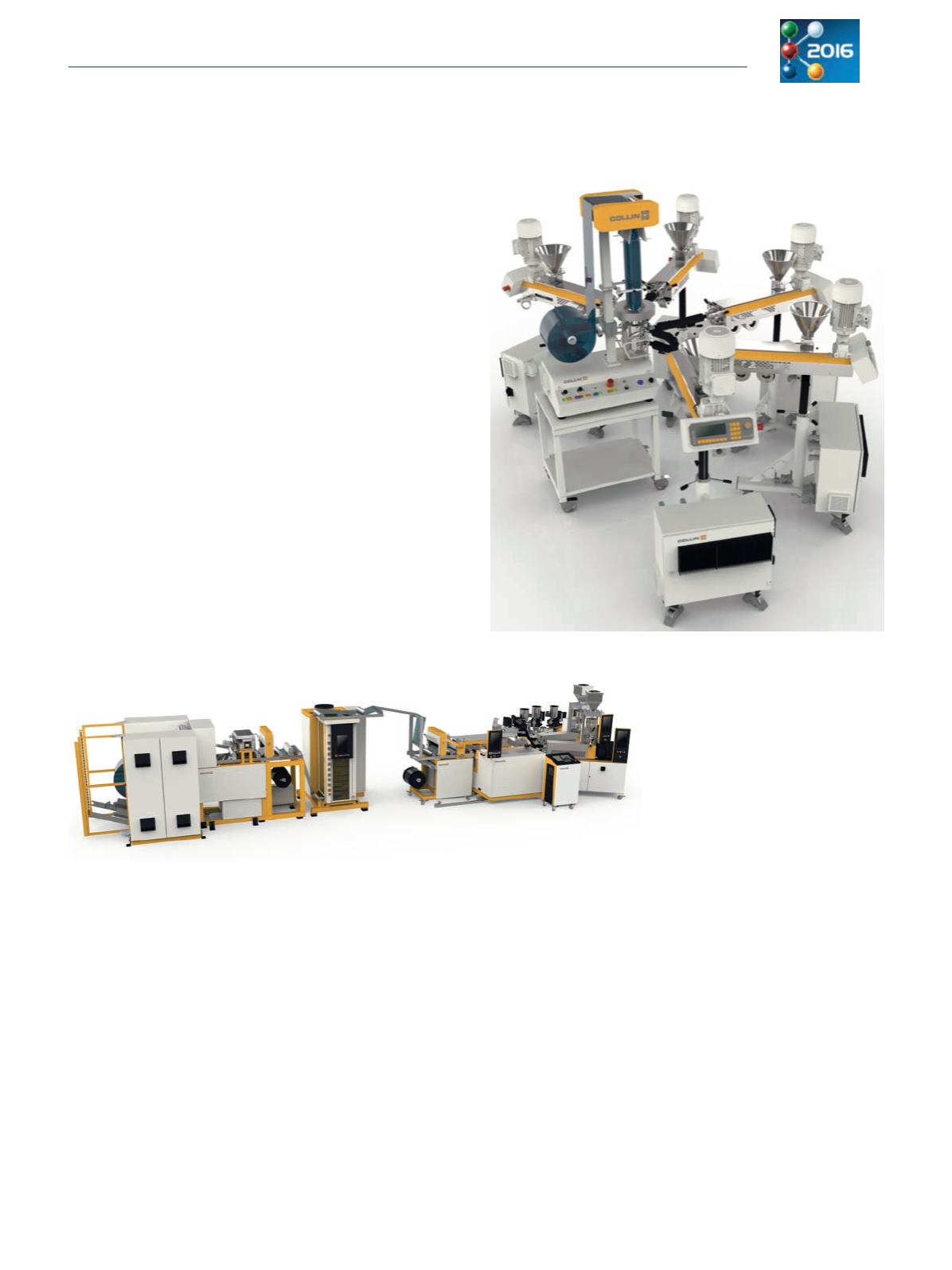

nnovation, efficiency, economy, reproducibility, upscaling &

modularity – under the slogan “future is now”, for Collin,

these keywords are taking center stage during this year’s Kex-

hibition appearance. The company presents: Cast/calendering-

MDO line with a length of 12 m, including a wealth of

innovative individual components, the new E Entrance series

extruder, the Collin multi-inspection, a 5-layer coextrusion line

and a Collin Medical Line.

The Collin GmbH intensely deals with subjects and challenges

of the plastics industry and incorporates this in its product and

line development under „future is now“. “With our know-

how, we guarantee that, already today, our customers deve-

lop, test or produce their products of tomorrow”, explain DI

Dr. Friedrich Kastner, CEO Colllin and Corné Verstraten, CSO

Collin.

Highlight Calender-MDO line – 12 meters of innovation

Greatest highlight, in two ways, is a line with a total length of

12 m, which exactly corresponds to the Collin product philo-

sophy of modularity, because it consists of the following, in-

novative and partly brand new individual components:

· Compounder Type ZK 25 P – with optimized throughput and

torque

· High speed Torque Extruder Type E 30 T – one of the Collin

innovations 2016

· Extruder Type E 30 P with new features/extras

· 5-layer feedblock with a 500 mm slot die

· 3-roll calender with gap control

· Take-off unit with start-up winder and COFIS film inspection

· MDO with double stretching gap

· Take-off module with various features (e. g. edge cutting,

film edge control)

· Collin turret winder, adapted to Collin lines

“So to speak, the complete line consists of Collin innovations

and improvements as for example the controls for extruders,

calenders, MDOs and winders. The system acquires all para-

meters and records them for evaluation. For the K-show, the

speed of the calender is max. 38 m/min and the MDO has a

speed of max. 100 m/min., of course, higher speeds can be

realized on demand. Furthermore, the line can be delivered as

Dr.Collin:

„future is now“

high-temperature version”, explain

Kastner and Verstraten.

Advantages of the Calender-MDO-

line – convincing in every meter:

· A higher degree of automation

due to motor-driven gap adjust-

ment of MDO and calender as well

as the new turret winder.

· Moreover, the motor-driven gap adjustment guarantees hig-

her reproducibility.

· Larger range of throughput because of the Extruder Type E

30 T. Thus, this results in a considerably larger process window.

· Here, modularity is decisive, since, depending on the requi-

rement, the components can be combined according to the

modular principle of Collin.

· With the new Collin auxiliary winder, which can wind both,

web material and edge cutting material, starting the machine

is considerably easier.

· Furthermore, with the turret winder it is possible to keep the

line running, also with long testing or production runs. Thus,

process stability and reproducibility can be increased. Moreo-

ver, it is not insignificant that personnel costs can be reduced.

· Production-related speed allows better upscale possibilities.

Extrusion International 5/2016

79