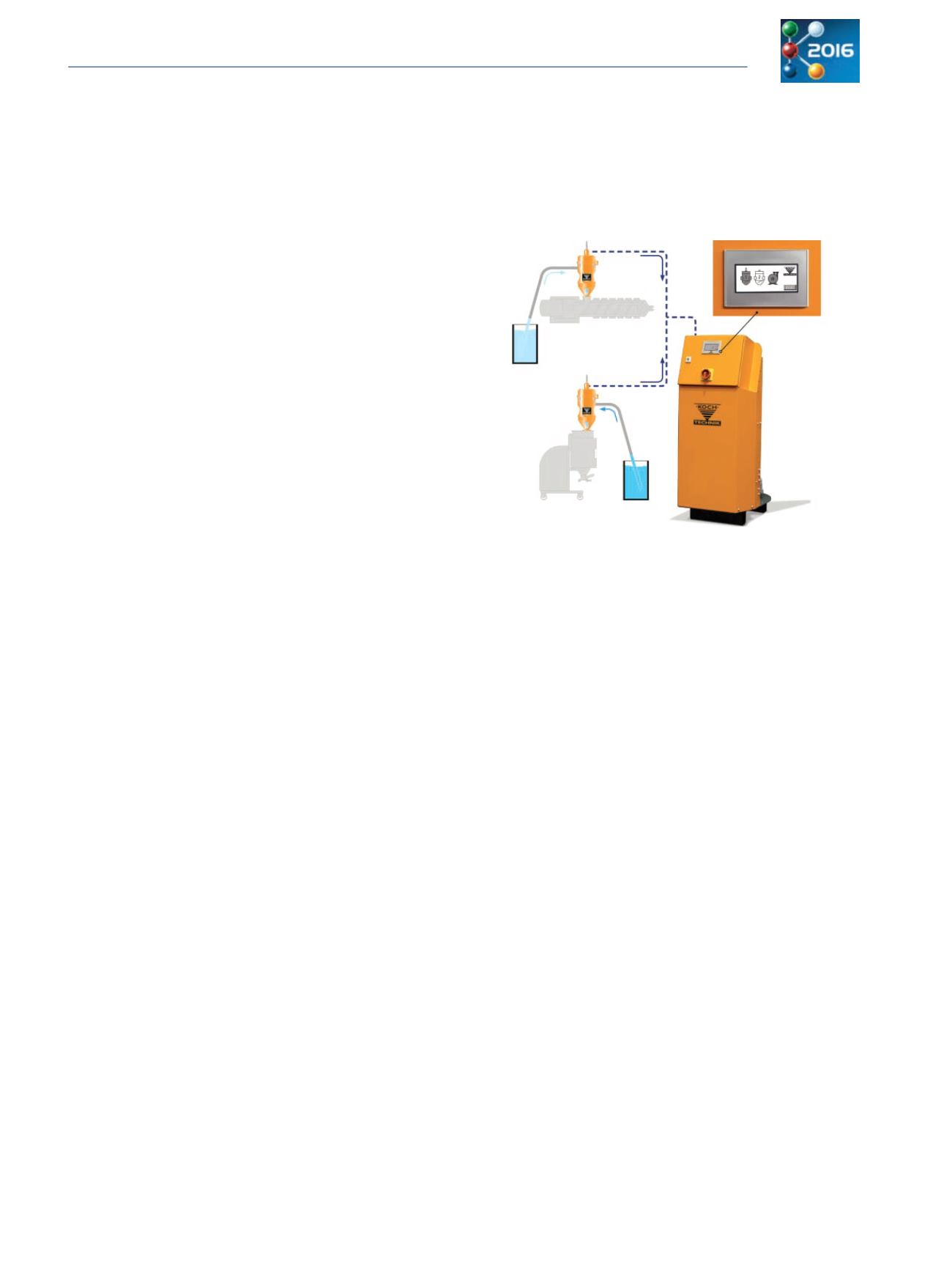

KOCH-TECHNIK:

DUO conveyor unit that supplies

two demand points

A

t this year’s K trade fair, KOCH-TECHNIK will be demon-

strating an economical conveyor that is able to deliver ma-

terial to two plastics processing stations or granulate dryers.

The designation Duo conveyor is used for various packages

put together consisting of a frame with a vacuum generator

and control system as well as two material hopper loaders with

hoppers allowing material throughputs of between 120 kg/h

and 340 kg/h. In contrast to KOCH-TECHNIK’s standalone

conveyors, DUO conveyors have only one single three-phase

vacuum generator; the output of this vacuum generator is ef-

ficiently distributed to two material conveyors on an alterna-

ting basis. The benefits for plastics processors are clear to see:

In addition to proven quality from Koch-Technik that ensures

trouble-free transportation of materials, customers receive a

package that provides the same performance at a more fa-

vourable price than two standalone conveyors. A uniform con-

figuration of device components from KOCH-TECHNIK’s

modular system guarantees a “turnkey” solution for material

transportation that can be deployed immediately. While the

processing material is conveyed safely and reliably without any

dust emissions, the maintenance-free vacuum fan is used to

optimum capacity. Koch-Technik understands the target group

for this product to be those plastics processors who wish to

supply two demand points close to each other with medium

to large material throughputs.

Simple operation

Operation of these units is intentionally kept as simple as pos-

sible: A touch panel is used to configure the parameters for

the two hopper loders and the vacuum fan. One of 16 langua-

ges can be selected for menu navigation. When the unit is

commissioned, the layer control is set up in such a way that

parameters such as cleaning and inspection intervals are sim-

ply configured for both material conveyors and the entire unit

is then password protected via a hierarchical operator level.

For conveying operation, it will then only be necessary to ac-

tivate the device and make any adjustments to the conveying

time.

Material feeding as a package

Each package includes two customised intermediate hoppers

and material hopper loaders. The A series material conveyors

from KOCH-TECHNIK are equipped with rotary blade cleaning.

With this type of cleaning, the conveyor air transporting the

material is cleaned through a filter in the hopper loader. This

filter made of highly efficient polyester fleece retains dust and

foreign particles of up to 2µ in size. A rotary blade within the

filter cartridge rotates at lightning speed prior to each con-

veying operation, generating compressed air to clean the filter

itself, from the inside to the outside, in less than 0.4 seconds.

This cleaning operation – which is highly efficient even when

ground material is being conveyed – ensures absolutely dust-

free transportation of materials within production and protects

the vacuum generator.

In the case of packages 1 to 3, a vacuum generator with an

output of 1.5 kW even provides for transportation of a total of

between 120 kg and 230 kg of raw material per hour. Package

4 deploys a powerful 2.5 kW vacuum fan to convey up to 340

kg/h. Two suction lances, antistatic PVC hose and a vacuum Y-

branch rounds off each complete package.

For more than 40 years, the name of KOCH-TECHNIK has

been synonymous with innovation, precision, modular flexibi-

lity and cost-effectiveness in the mixing, dosing, conveying,

drying and storing of plastic granulates. Use of our equipment

and systems in more than 5,000 plastics processing compa-

nies around the world is testimony to the acceptance and high

efficiency of these systems in everyday production work.

Hopper Loader

Material

Storage

IMM

Hopper

Loader

Material Dryer Material

Storage

DUO Feeding unit

DUO Touch

Panel Control

The KOCH-TECHNIK DUO conveyor unit is able to deliver material

to two plastics processing stations or granulate dryers

Hall 10, Booth A21

➠ www.koch-technik.comExtrusion International 5/2016

81