BYK:

fresh Look with an innovative Additive

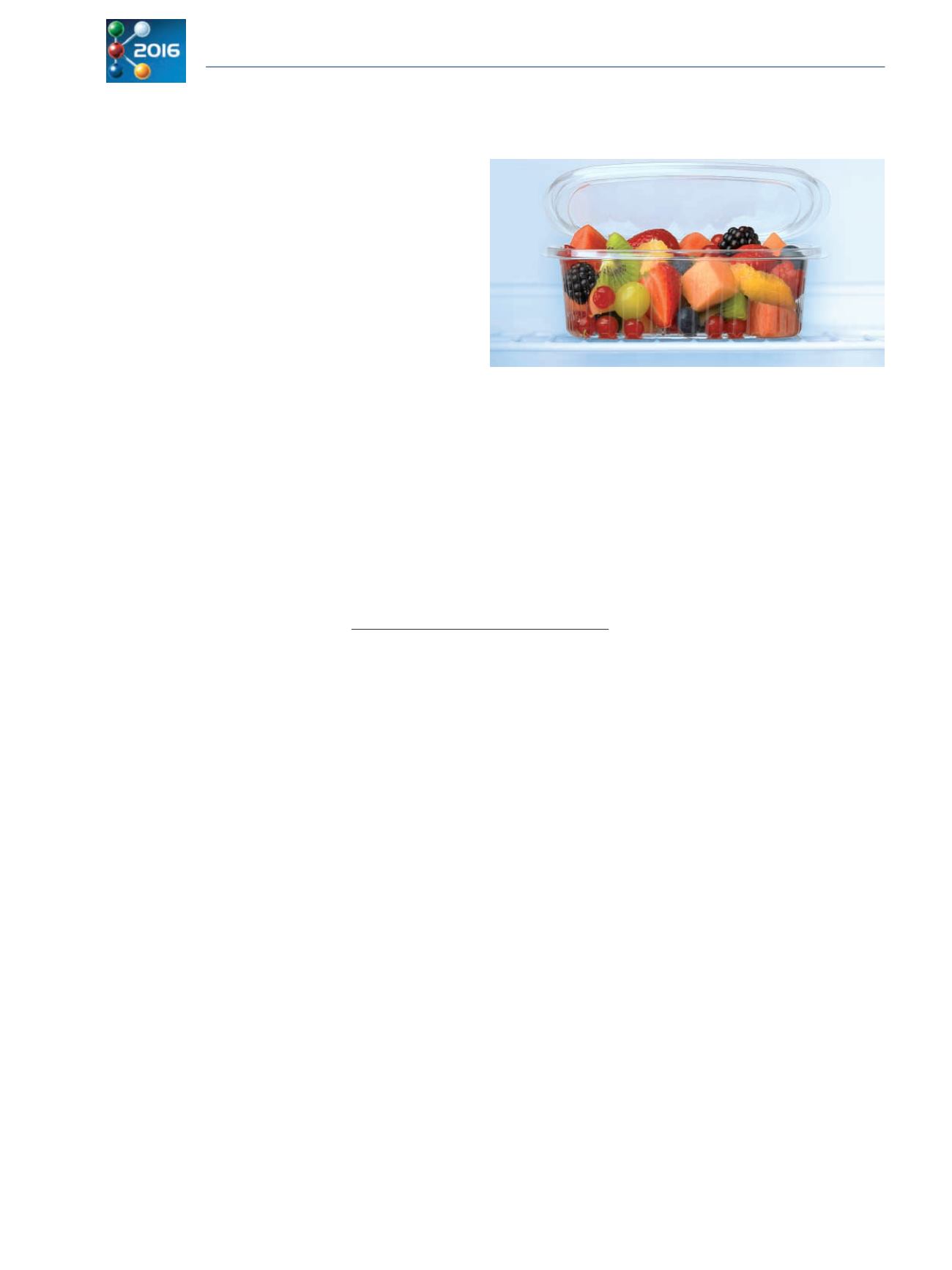

F

reshness is a mega trend in the food sector, even with con-

venience products. Consequently, refrigerated food units

take up an increasingly greater part of the supermarket. That’s

because consumers favor products that contribute to a heal-

thy diet and that ensure their shelf life by refrigerating instead

of adding preservatives. Modern packaging must therefore

meet the growing demands for freshness and the call for eco-

logical friendliness more and more.

BYK, a leading manufacturer of additives and measuring in-

struments for the plastics and coatings industry, is joining the

packaging industry in this consumer trend for fresh foods and

sustainable packaging with its new barrier additive

BYKO2BLOCK-1200. This unique barrier additive has been

specially developed for use in PLA-based food packaging. Due

to the even distribution of the layered silicate platelets in the

polymer matrix, a very effective barrier layer is built up, which

brings about a significant reduction in gas and water vapor

permeability. Hence, the food stays fresh longer in the packa-

ging. Another trade fair highlight will be the extended pro-

duct portfolio for thermoplastic applications due to the

acquisition of Addcomp B.V. Additives with different functio-

nalities such as flame retardancy, thermal and UV stabilization,

anti-fogging action, and nucleation will be part of the product

range from now on.

Packaging example of PLA-based food packaging

involving a BYK barrier additive

Hall 5, Booth E17

➠ www.byk.comRiverdale Global:

liquid Blowing Agents

A

new series of liquid blowing agents for use with a wide

range of resins provides improved dispersion and more

controlled foaming action than pellet masterbatches while

being used at lower addition levels, it was announced today by

Riverdale Global. The company will introduce the additives at

K 2016 (Hall 10, Stand A 26).

The chemical blowing agent (CBA) formulations available in

the new +Foam™ series of liquid additives include the stan-

dard exothermic azodicarbonamide CBA, an endothermic

CBA, and a combination of the two. All are used at 0.5 to

1.5% letdown ratios, which are lower than levels typically re-

quired for pellet masterbatch. Among the resins with which

they can be used are polyolefins, polystyrene, ABS, PPO, and

other polymers.

“Because +Foam liquid blowing agents avoid the heat history

required for manufacturing pellet masterbatches and are more

gently mixed into the base resin, pre-decomposition of the

CBA is less of a concern,” said Charles B. Irish, vice president

of product development. “For users of +Foam products based

on an endothermic CBA, there is the added benefit of shorter

cycle times, since the CBA adds less heat to the process.”

Because liquid additives can be metered into the process with

precision and disperse more uniformly in the melt than ma-

sterbatch, processors are better able to achieve the target level

of density reduction, noted Mr. Irish. “Use of Riverdale Glo-

bal’s gravimetric metering system provides an additional level

of precision, allowing for controlled conditions over the entire

production run.”

By reducing the density of a molded or extruded product, blo-

wing agents make possible savings on raw material, contri-

bute to light-weighting in transportation applications, and

help processors to meet sustainability goals. Added at lower le-

vels, blowing agents can also be used to prevent sink marks

and warpage.

The new additives are available in pails or drums, in custom

blends with liquid colors, or as one of the GlobalPlus™ range

of liquid additives. In the GlobalPlus system, each additive is

supplied in a drum with a built-in pump that stay sealed

throughout shipping, handling, and processing.

Hall 10, Booth A26

➠ www.riverdaleglobal.comExtrusion International 5/2016

82