126

kompakt

Extrusion 7/2016

➠

Guill Tool & Engineering

www.guill.comFor a video please go to:

https://youtu.be/jeNovmMtcBsment system that significantly reduces

pressure on the tooling, allowing easier

and more precise concentricity adjust-

ments without loosening the face bolts.

Easy-Out inserts for the adjusting bolts

also allow simple replacement of locked

or damaged adjusting bolts, which fur-

ther saves on repair and downtime.

Another innovative feature of this new

rubber/silicone crosshead is a cast alumi-

num liquid-fed cooling sleeve that allows

the user to switch out the cooling jacket

in the event of a line obstruction, again

reducing downtime compared to tradi-

tional integrated cooling systems.

The new 500 Series crosshead with

MAGS gum space adjustment is a drop-

in replacement on most existing NRM

n

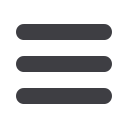

Guill Tool introduces the new 500 Se-

ries crosshead with MAGS gum space

adjustment. The 500 Series is designed

specifically for the flow characteristics

and unique processing challenges of

elastomeric compounds. One of the key

features on this new crosshead design is

the mechanically assisted gum space

(MAGS) adjustment system. This new

method of gum space adjustment allows

the operator to make an effortless ad-

justment from a single point using a

common socket wrench. No more need

to struggle with multiple nuts and bolts

in order to adjust gum space, which

leads to faster adjustments. The visual in-

dicator on the core tube allows the ope-

rator to see how far the gum space has

been moved, making those adjustments

much more accurate and repeatable.

The hardware-free and patented cam

lock design of the new 500 Series means

no time is wasted unbolting and re-se-

curing fasteners for disassembly and re-

assembly. Only half of a rotation of the

cam nut is required to loosen and auto-

matically extract the deflector from the

head body, which is another time saver.

Also, with no undercuts on the deflector,

there are no material hang-ups when ex-

tracting the deflector, allowing for faster

and easier cleaning and changeover.

The new 500 Series also features the la-

test Center-Stage concentricity adjust-

New 500 Series Rubber/Silicone Extrusion Crosshead

lines, however this crosshead design can

also be adapted to fit any extruder de-

sign or line layout.

The addition of a newly designed flow

inlet channel reduces the shear and heat

that is generated as the materials are

being processed. This leads to lower

head pressures allowing the material to

move through the head in a much more

balanced and even flow.

All crossheads supplied by Guill are fur-

nished with a tool kit for assembly and

disassembly as well as a detailed opera-

tor’s instruction manual.

Guill Series 500 crosshead with Mechanically

Assisted Gum Space (MAGS) adjustment…

specially designed for the flow characteristics of

elastomeric compounds

roll silicone coater. Both technologies are

capable of high rates and ease of main-

n

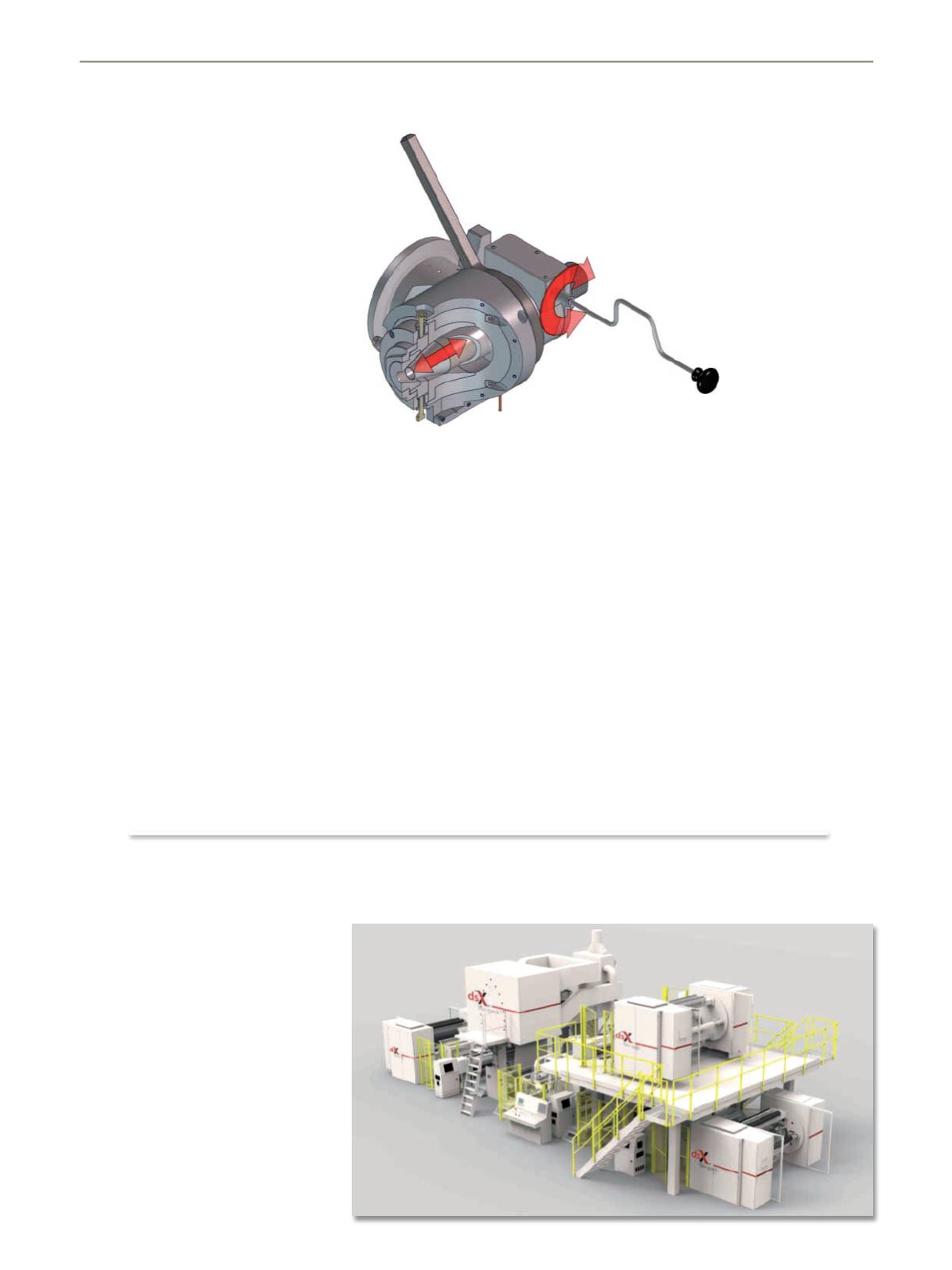

Davis-Standard showcased the com-

pany’s versatile converting technology

and offered live demonstrations at its

nearby ER-WE-PA Gmbh facility in

Erkrath during drupa 2016. Davis-Stan-

dard has seen signficant growth in liquid

coating applications as well as demand

for cost-effective, high productivity pro-

cessing systems. The company has ad-

dressed these markets with new liquid

coating advances and an innovative line

of dsX™ technology for extrusion

coating, cast film and blown film appli-

cations.

In liquid coating, Davis-Standard deve-

loped a new curtain slide coater and five-

Converting Technology

tenance. The curtain slide coater applies

single layer coatings at rates up to 2800

dsX flexpack