37

Extrusion Asia Edition 1/2016

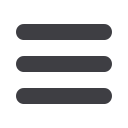

B

REYER extruders are designed to

operate with low energy use and as

much as comfortable for the operator.

All e-cabinets are equipped with

Siemens control unit. The comfortable

operations works via touch-display. The

vented extruders are running very eco-

nomically, since time-consuming and

energy-intensive pre-drying of the resin

is not necessary. On top the extruders

showing a high specific output. The wa-

ter-cooled AC motor is running extre-

mely quit.

Furthermore the extruder can be flexible

equipped with different kind of screen

changers as well as with a melt pump.

The special melt pump control allows a

quick and safe start-up. In this way it

saves raw material. An extrusion T-die

with rapid gap adjustment allows the

quick adjustment of the die lip during

production.

To adjust the die bolts of the flexlip

quickly and safe, an optional bank mea-

suring system permanently control the

melt bank. It informs the operator via

monitor which die bolt has to be adjus-

ted. In this way the profil can be set in a

very short time an safes raw material.

The calender is the quality hub of the

line. For gap adjustment in the past,

mechanism were built into the calen-

ders which allowed a more or less pre-

cise setting of sheet thickness. From a

simple adjusting screws and handwheel

adjustment right through to a moto-

rized adjustment method, which adjus-

ted the gap between two rolls, all kinds

of mechanism were available. By these

methods the sheet thickness was adjus-

ted in the calender. The BREYER gap ad-

justment fast&easy does not involve

any mechanical adjusting parts. A so-

phisticated system permits precise posi-

tioning, accurate to within five thou-

sandths of a millimeter! Amazingly, this

precision is achieved during production

and at full load! The system allows gap

settings to be set in the range of 0 to

100 mm with exactly the same preci-

sion. However, with film and sheet ex-

trusion this is generally between 0.1

and 20 mm.

The set-points are entered via a color

touch screen. The gap immediately

changes then at a touch of a button.

This technology of gap adjustment re-

presents real progress in extrusion tech-

nology, as it gives the user much greater

freedom and sets new standards in

terms of the speed and precision of pro-

duct thickness settings.

Free lateral accessibility and view into

the roll gap is given by the arrangement

of the rolls. Thus also e.g. dies with de-

ckeling systems could be applied with-

out colliding with the machine frame.

Decoration films could easily be guided

into the roll gap by means of a prepared

unwinding device at the calender.

Changing embossing design:

For the fast change of the middle roll

this roll is located in a drawer which

ejects by push of a button within few

seconds and could be exchanged by a

roll with another embossing design.

This function is very comfortable for the

operator because with this the roll is

freely accessible and could be lifted out

by means of a crane.

Split bearings and fast couplings at the

drive and cooling side allow a rapid re-

lease of the precise connections. In ope-

rating mode the roll is hydraulically

locked and immediately ready for appli-

cation. With this system the change of

rolls could be finished within a few mi-

nutes.

Yet another feature which improves the

efficiency of the complete extrusion

line. BREYER will present this system at

the exhibitions 2016 in a 3D video ani-

mation.

Chinaplas 2016: Stand E1F15

Breyer GmbH Maschinenfabrik

Bohlinger Str. 27, 78224 Singen, Germany

www.breyer-extr.com