下个月,Maguire有限公司将按计划发运第

五 万 套 Maguire® 称 重 混 合

机,

并将在2016年中国国际橡塑展(展台号

E7K21)

期间启动长达一年的庆祝活动,以纪

念塑料行业的这一里程碑。

在Maguire的展台上,将展出一台独特的镀

铜版MicroBlender™混合机,这是公司生产的非

常流行的系列混合机中的最小型号。接下来的

几个月,这台混合机将作为纪念品,在公司遍

布全世界各地的代理商及其客户所在地的庆祝

活动中,作为销售里程碑的标志进行展示。

“Maruire混料机是世界使用最广泛的称重

混料机,被用于每一种场合,包括模塑、挤出

和混料加工,市场范围从汽车行业到电线电

缆。” Maguire亚洲私人有限公司的董事总经理

Hubert Nerlich说道,“1989年,Maguire的董事

长和首席设计师Steve Maguire开发出第一台称

重式批次混料机,彻底改变了原料经过计量添

加到塑料加工机械的方式。”

称重式批次混料机按照目标比例,将每一批次的原料依

次分配到称重室,这样,通过监视每一个批次重量的增加,

混料机控制下一批次作出调整,以保持精度和控制物料消耗

量。Maguire销售有限公司副总裁Frank Kavanagh指出:系

统的批次计量精度保持在+/- 0.1%以内, “要想在原料混合中对

混合物料的成分进行精密控制,Maguire公司的称重式批次混

料机是第一台价格实惠而且易于操作的系统。这一创新对整

个行业来说,节省了大量的物料成本,并且提高了产品的质

量。混料机与控制系统以及Maguire公司所开发的软件结合起

来,同样具备高级功能,方便地与各种处理器实现存取联

接,包括每一个批次的可追溯性和文档化,挤出产量控制,

以及工厂自动化。”

这种组合易于使用,功能强大,在Maguire公司引入的

新的标识上,“智慧而朴素” 这个口号是集中的体现。同

样,在整个庆典年里,新的图标 “50K”(意为:五万套)将出

现在Maguire 公司的媒介资料上。

M

aguire Products, Inc. is on course to ship the 50,000th

Maguire

®

gravimetric blender in coming months and will

inaugurate a year-long celebration of this plastics-industry mile-

stone at

Chinaplas 2016 (Booth E7K21)

.

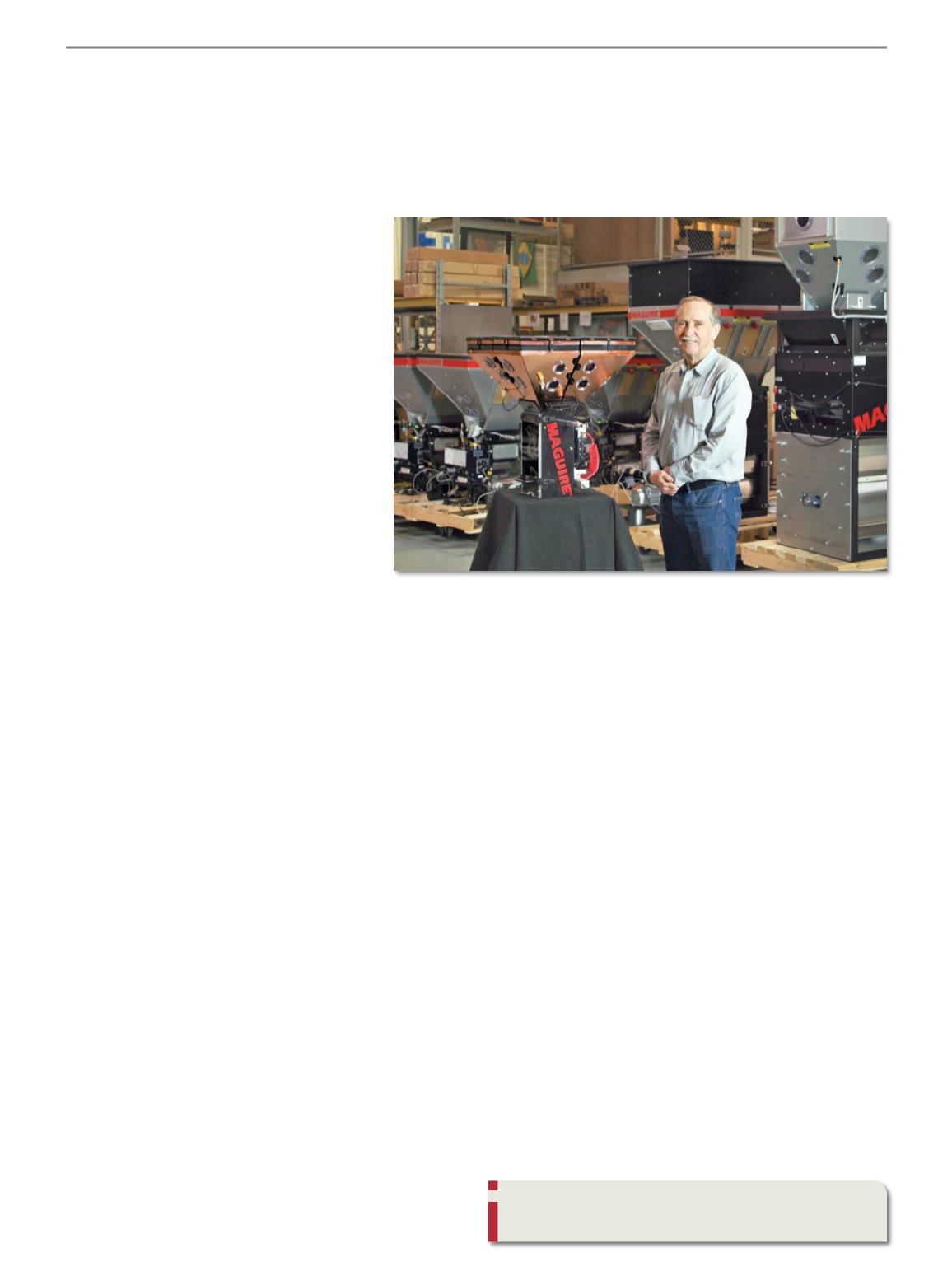

On exhibit at the Maguire booth will a unique copper-plated

version of the company’s widely used MicroBlender™, the

smallest model in the Maguire blender range. In following

months, this celebratory blender will be on display at local

events around the world as the company’s agents and their

customers mark the milestone sale.

“The Maguire blender is the world’s most widely used gravime-

tric blender, employed in every type of molding, extrusion, and

compounding process and in markets ranging from automotive

to wire and cable,” said Hubert Nerlich, managing director of

Maguire Products Asia Pte Ltd. “When Maguire president and

Maguire Products, Inc.,

Maguire Asia (Chi na), www.maguire.com, mpa@maguirechina.com“世界之旅”将在2016年中国国际橡塑展期间启航

‘WORLD TOUR’ will be opened at Chinaplas 2016

chief designer Steve Maguire developed the first gravimetric

batch blender in 1989, he revolutionized the way raw materials

are metered into the plastics processing machine.”

A gravimetric batch blender sequentially dispenses each batch

ingredient in its target proportion into a weigh chamber; then,

by monitoring each gain in weight of a batch, the blender con-

trol makes adjustments to subsequent batches to maintain ac-

curacy and control raw material consumption. The Maguire sys-

tem holds batch accuracy to within +/- 0.1%, according to

Frank Kavanagh, vice president of sales for Maguire Products,

Inc.

“The Maguire gravimetric batch blender was the first afford-

able and easy to operate system for precisely controlling the

composition of a raw material blend,” said Frank Kavanagh.

“Throughout the industry it has generated substantial savings

in material costs and increases in product quality. In combina-

tion with control systems and software developed by Maguire,

the blender has also made advanced capabilities readily accessi-

ble to a wide range of processors, including lot-to-lot accoun-

tability and documentation, extrusion yield control, and factory

automation.”

This combination of ease of use and powerful capabilities is re-

flected in a new logo tagline that Maguire is introducing: “In-

telligent Simplicity.” Also new is a “50K” icon that will appear

on Maguire communications throughout this celebratory year.

Steve Maguire 及庆典纪念品 MicroBlender™

Steve Maguire with celebratory MicroBlender™

47

Extrusion Asia Edition 1/2016