of the Discovery ring, the dosing unit, the EAGLE sensor and

the thermal modulation in a close loop. The whole production

control is summarized by Navigator 9000, a 15 inch touch

screen where the entire process is displayed. The core of the au-

tomation is Navigator 9000, a powerful computer which con-

trols and manages every parameter through a special algorithm

named BATCH TIMING SYSTEM, able to automatically start the

production in only two minutes. A GUINNESS WORLD

RECORD.

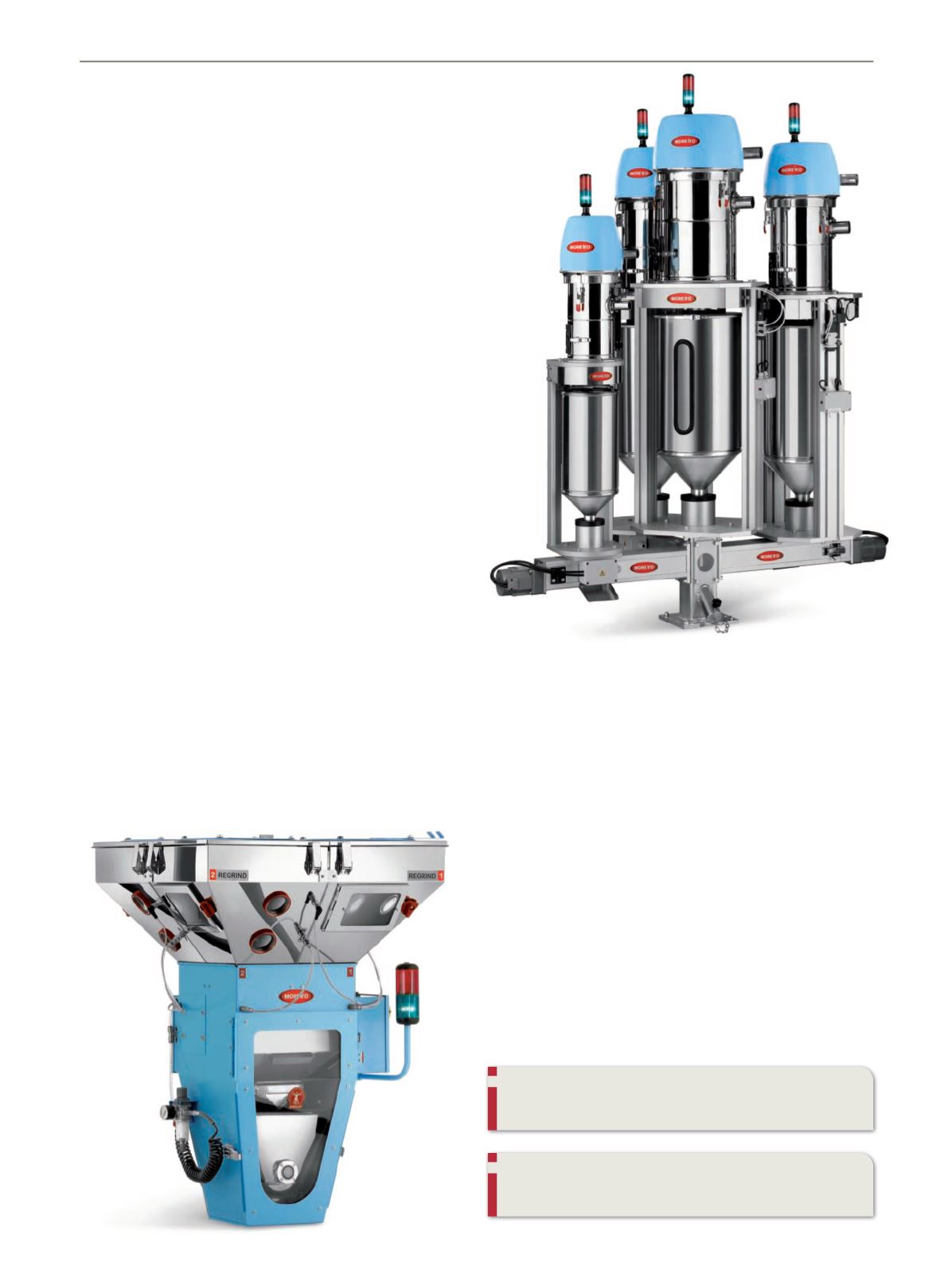

GRAMIXO DBK

: A continuous gravimetric dosing system with

an extruder control very suitable for bubble film production.

The advantages of the double eye lid and the Vibration Immu-

nity System patented technology are combined with the advan-

tages deriving from the special “batch timing system” algo-

rithm, allowing a very high reading frequency and an une-

qualled precision: 4,000 readings per second.

The Vibration Immunity System, the free weighing hopper and

the digital technology enables an extreme precision even in pre-

sence of high vibrations.

Two weighing cells weigh the material decrease in the mixer

and ensure that the extruder correctly observes the schedule

with a direct relation and control on the haul-off in order to

guarantee the highest precision in the weight/linear metre

ratio.

The system is set for up to eight direct dosing units. A powerful

microprocessor controls the machine with a 10 inch touch view

and makes the operator interface simple for management acti-

vities.

The possibility to extract the mixer for production change ope-

rations is an important and unique Gramixo feature.

Weight/metre control is an essential equipment for a quality

process. Gramixo can be connected to a supervising system

that allows to control, collect and store data from several

plants.

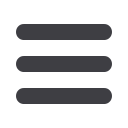

GRAVICO DLK

: The Moretto continuous loss in weight dosing

system from two to eight stations, a multi component gravime-

tric dosing system with an automatic weight/linear metre.

23

Extrusion 2/2016

Regulation, fitting all continuous cycle systems for plastics pro-

cessing where a constant component feeding and perfect dos-

ing are required. This operation is independent from the mate-

rial specific weight and, moreover, process control is constant.

The system works by continuous weight loss, self-adaptive to

production requests and allowing high savings. Gravico con-

trols the film weight and thickness and adapts the production

to the line speed: a simplified interface and a touch screen con-

trol make the system easy and flexible. The finely balanced

weighing cell, and the advanced electronics allow to manage

also complex situations. The system needs no maintenance ac-

tivities thanks to its simple mechanical concept. The start-up

phase is very fast and allows production starts and changes in

only two minutes. Extreme modularity and production stability

are based on an automatic system and increase productivity

and supply repeatability keeping quality constant.

The construction and the working principle guarantee a perfect

material mixing avoiding materials and additives stratification.

GRAVICO is compatible with MOWIS supervising system.

Contrex s.r.l.

Via dell’Artigianato, 4, 31034 Cavaso del Tomba, TV, Italy

www.contrex.itMORETTO S.p.A.

Via dell'Artigianato 3, 35010 - Massanzago, PD, Italy

www.moretto.comGRAVICO DLK

GRAMIXO DBK