schalten und bei Wartungsarbeiten mit

einem Handgriff tauschen. Im Transport-

band frei positionierbare Saugstationen

befreien mit ihrem intensiven Luftstrom

die Stränge vom anhaftenden Wasser-

film. Mit wenigen Handgriffen ist die

Strangnachkühlung wahlweise auch auf

intensive Kühlung umstellbar. Eine

Strangtrocknung im letzten Förderban-

dabschnitt sorgt dafür, dass das Material

beim Einzug in den Granulator nur noch

eine sehr geringe Restfeuchte hat.

Die neue automatische Bandzuführung

von Coperion kann für ein breites Mate-

rialspektrum eingesetzt werden. Hierzu

hat sie standardmäßig eine Höhenver-

stellung, um den unterschiedlichen Auf-

setzpunkt der extrudierten Stränge auf

der Wasserrutsche je nach verarbeitetem

Material einzustellen. Für die Absiche-

rung der hohen Abzugsgeschwindigkei-

ten bei zugleich hohen Strangzahlen und

damit hohen Durchsätzen im automati-

schen Betrieb ist eine Strangüberwa-

chung integriert. Bei Kombination mit ei-

nem Coperion-Extruder lässt sich die

Steuerung der Strangzuführungseinheit

auch direkt in die Extrudersteuerung in-

tegrieren, was den Bedienaufwand

nochmals reduziert.

D

esigned to work in conjunction with

Coperion's two large strand pelleti-

zers, the SP 500 HD (working width

500 mm) and the SP 700 HD (700 mm),

this new conveyance system is likewise

available in two sizes: the ASC 500 for

throughput rates of up to 3.5 tons/hour

and the ASC 700 for up to 5 tons/hour.

The conveyance system automatically

guides the extruded strands via a cooling

water chute and downstream conveyor

belt into the feed mechanism of the pel-

letizer. A likewise automatic start-up me-

chanism facilitates the start-up opera-

tion, while any possible machine mal-

functions caused by broken strands are

avoided by the system's ability to rethre-

ad the strands. Compared to other pro-

cesses, strand pelletizing ensures an ex-

tremely gentle treatment of the product,

as it operates with much lower pres-

sures. Other convincing advantages are

the reduced complexity of the system

and the low rate of wear. These benefits

combined with its relatively low operat-

ing costs make strand pelletizing an ob-

vious choice for the compounder.

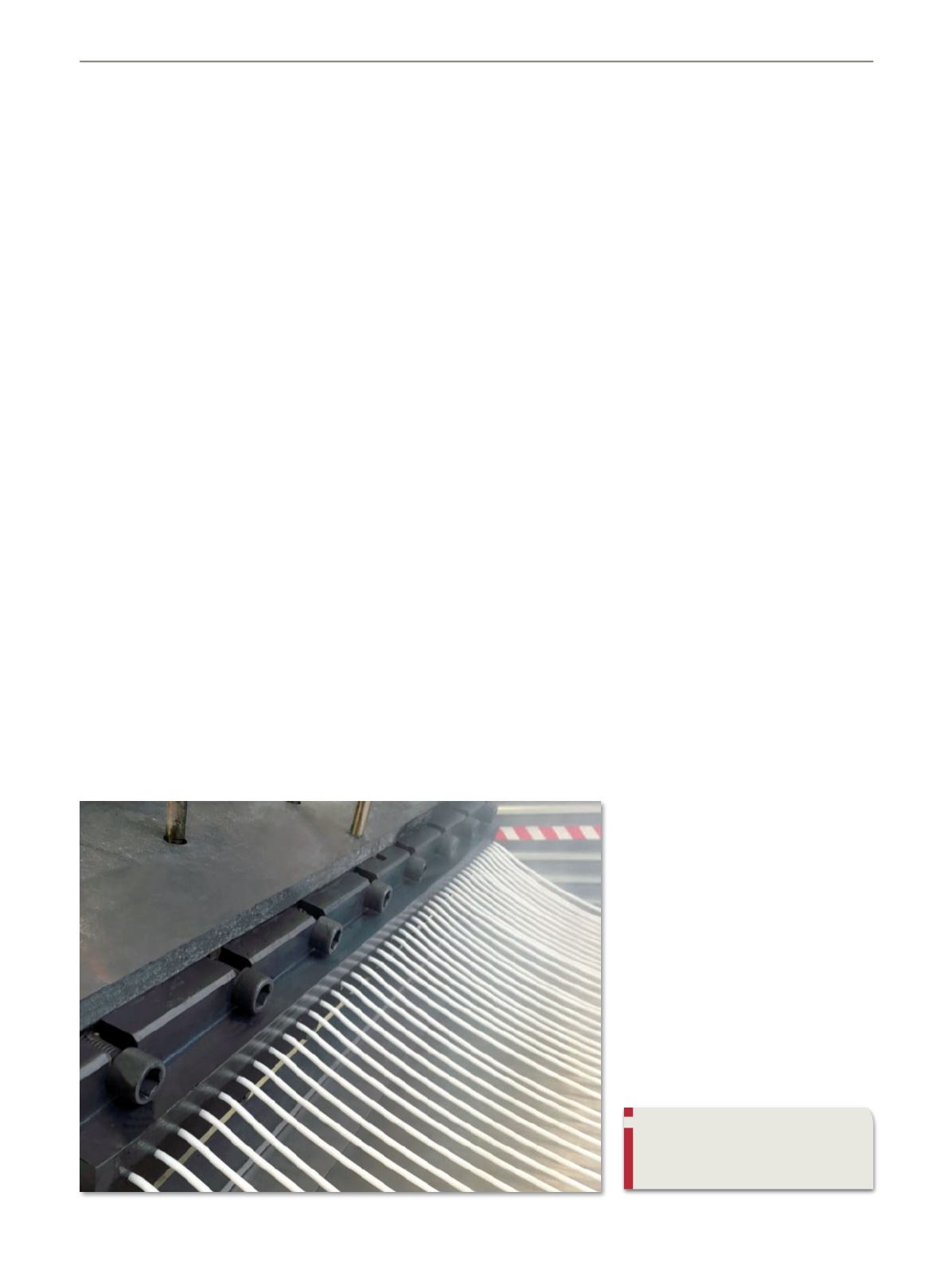

The new SK92 die head has been deve-

loped specially for high throughput

rates. Homogeneous heating/cooling en-

29

Extrusion 2/2016

Coperion Pelletizing Technology GmbH

Theodorstr. 10, 70469 Stuttgart, Germany

www.coperion.comsures completely uniform extrusion of

the strands across the entire width of the

extrusion die. The die head is distin-

guished by its optimal rheology and effi-

cient heat transfer, providing maximum

possible throughput while ensuring

gentle handling of the product. This fea-

ture makes the SK92 die head ideally

suited to the increased throughput capa-

bilities of the ZSK Mc18 extruder series.

The ASC automatic strand conveyance

system is modular, permitting flexible

and rapid adaptation to the require-

ments of the process. If, for example, the

extruded material requires more inten-

sive cooling, the strands – after being

cooled in the water chute – can also be

spray-cooled with cold water on the

downstream perforated conveyor. The

spray bars used for this purpose can be

turned on and off individually and can be

readily exchanged during regular main-

tenance operations. Freely positionable

suction stations in the conveyor system

generate powerful streams of air that

free the strands from adhering water.

This post-cooling unit can also easily be

converted to an intensive cooling sec-

tion, if required. A strand drying unit in

the last section of the conveyor system

ensures that residual moisture is abso-

lutely negligible when the strands are

fed into the pelletizer.

Coperion's new automatic strand con-

veyance system may be used for a broad

spectrum of materials. It is equipped as

standard with a vertical adjustment per-

mitting different points of strand place-

ment on the water chute depending on

the material being processed. An inte-

grated strand monitoring device helps to

maintain high take-off speeds in con-

junction with a high number of strands

and hence high throughput rates in fully

automatic operation. Combination with

a Coperion extruder permits direct inte-

gration of the strand conveyance control

into the control system of the extruder,

thus affording yet a further reduction in

operating effort.

Der neue Spritzkopf SK92 von Coperion wurde speziell für hohe Durchsätze

entwickelt

Coperion's new SK92 die head has been specially developed for high

throughput rates