Medical Plastics 2016

25. -26. 04. 2016

Bangkok / Thailand

曼谷/泰国

‡

TechnoBiz

www.medicalplastics-expo.comCHINAPLAS 2016

25. - 28. 04. 2016

Shanghai / P.R. China

上海/中國

‡

Adsale Exhibition Services Ltd

www.ChinaplasOnline.comPlastpol

17. - 20. 05. 2016

Kielce / Poland

凯尔采 / 波兰

‡

Targi Kielce

www.targikielce.pl/enArgenplás 2016

14. - 15. 06. 2016

Buenos Aires / Argentina

布宜诺斯艾利斯 / 阿根廷

‡

www.argenplas.com.arRosplast / Rosmould

15. - 17. 06. 2016

Moscow / Russia

莫斯科 / 俄国

‡

rosmould.com,

rosplast-expo.com19th PPPExpo Africa 2016

12. - 14. 07. 2016

Dar-es-Salaam / Tanzania

达累斯萨拉姆 / 坦桑尼亚

‡

EXPOGROUP

www.expogr.com/tanzania/pppexpo/

4th Maynmar Int’l

Plastics, Rubber Packaging, Printing &

Foodtech Industrial Exhibition

15. - 18. 07. 2016

Yangon / Myanmar

仰光 / 缅甸

‡

Chan Chao Int’l Co., Ltd

www.myanmar-expo.comK 2016

19. - 26. 10. 2016

Düsseldorf / Germany

杜塞尔多夫 / 德国

‡

Messe Düsseldorf GmbH

www.k-online.de06

信息縱覽

Extrusion Asia Edition 1/2016

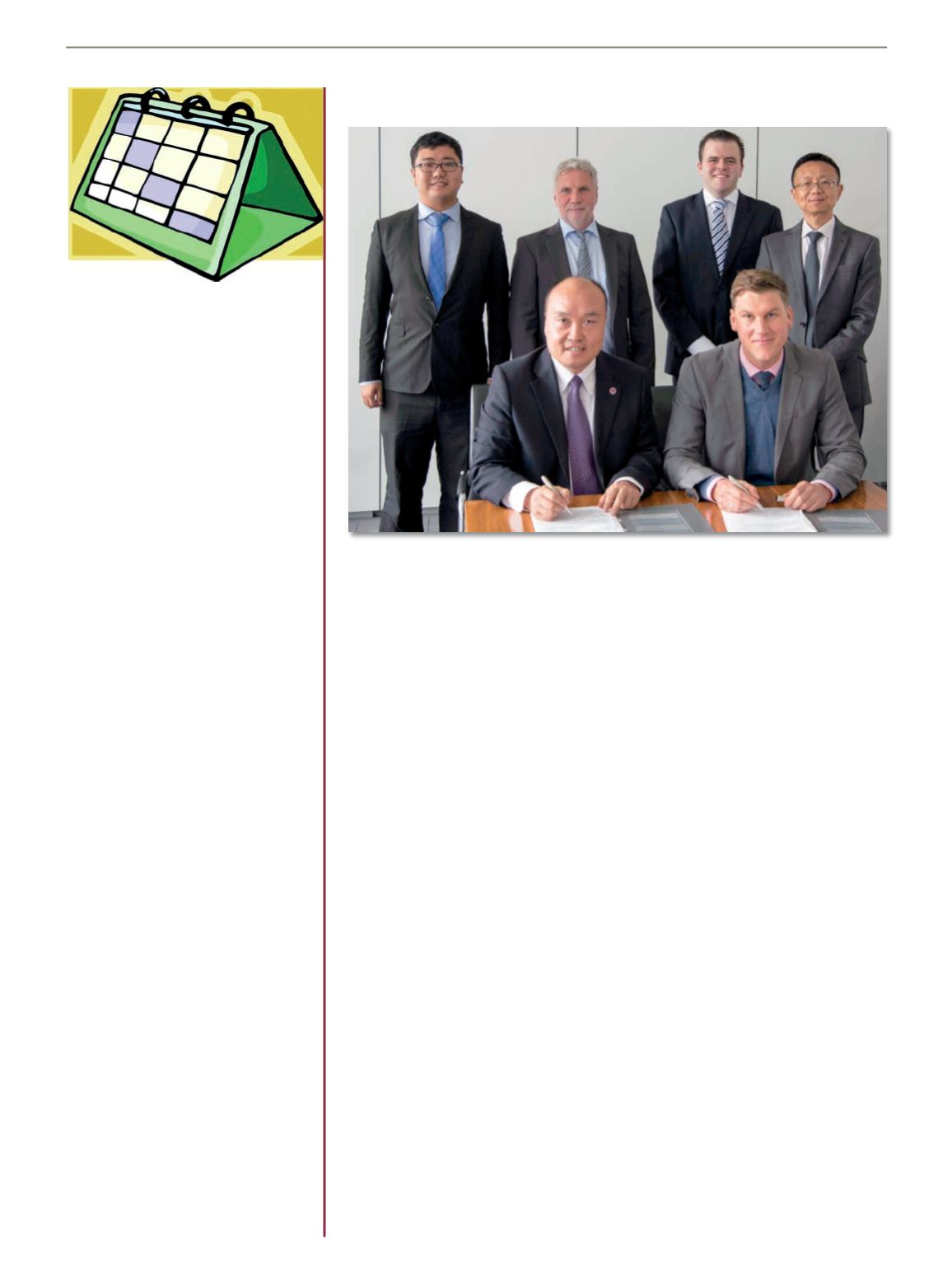

site Co., Ltd. signed a contract for two

fully automated HP-RTM plants for the

manufacture of carbon-fiber-reinforced

plastic components for the automotive

industry. This is already the second major

order for state-of-the-art production

lines for lightweight components from

China within a short period of time. In

April, the Chinese-American joint ven-

ture CSP Victall ordered a production line

for the manufacture of long-fiber-

reinforced plastic components.

Both HP-RTM (high-pressure resin trans-

fer molding) plants are used to produce

parts such as class A-compliant exterior

components using the new surface RTM

method. The core of the delivery is two

DCL upstroke presses with pressing for-

ces of 3600 and 2500 tons.

In the surface RTM procedure, co-deve-

loped by Dieffenbacher, carbon compo-

nents with surfaces that can be painted

directly are manufactured without any

manual reworking. The first step in this

manufacturing process is to press a con-

ventional RTM component. Next, the

press is opened a small amount and a

primer is injected to compensate for any

sink marks or surface imperfections. The

result is premium class-A components

produced in only one cycle.

n

康得复合材料有限公司的专家在金

秋10月签署了一份合同,购买2套全自

动成套高压RTM设备生产线,为汽车行

业生产碳纤维增强塑料部件。这已是在

短期内与中国签订的第2份大订单,为

轻量化零部件生产引进最先进的生产线

。4月中美合资企业CPS Victall 曾订购

了一条生产长纤维增强塑料部件的生产

线。

这2条高压RTM(高压树脂注模成型

)生产线采用新的表面成型方法用于生

产A级标准的外饰部件。 注射的核心是

2台 DCL压 机 , 压 力 是 3600和 2500

吨。

由迪芬巴赫共同开发的表面树脂注

模成型工艺,碳纤维部件表面可以直接

油漆无需任何手工再次加工。这个生产

工艺的第一步就是压模一个常规的RTM

部件,然后压机稍微开启,注入底漆可

弥补缩痕或表面缺陷。这条生产线的成

就果是仅仅在一个生产周期内能完成A

级部件的生产。

北京康得投资集团是康得复合材料

有限公司的母公司,是中国最大的生产

腹膜的生产商,今后重心是生产最先进

的轻量化碳纤维部件。中国政府计划到

2020年推广五百万辆电动汽车

。

n

Lightweight Construction for E-

Mobility in China:

In October, the Chi-

nese plastics specialist Kangde Compo

-

业生产轻量化为中国电动汽车行零部件

康得复合材料公司与迪芬巴赫签订2条全自动高压RTM生产线时的合影

The partners of Kangde Composite Co. , Ltd. and Dieffenbacher at the signing of

the contract for two fully automated HP-RTM lines