49

Extrusion 5/2016

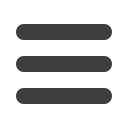

The ECO filter not only has a very compact design but is

also extremely durable. The interval between screen

changes can last several weeks or even months depen-

ding on the material and level of contamination. During

this time, the melt pressure remains stable. The unit is de-

signed to remove contamination levels as high as 1.5 per-

cent by weight. Two sizes are available depending on the

capacity requirements: The ECO 200 is for throughputs

up to 1,500 kg/h and as the ECO 250 for a maximum of

3000 kg/h. In addition to polyolefin melts, it is also suit-

able for filtering easy-flowing materials such as PET or PA.

With their compact, space saving design ECO melt filters

can be retrofitted in existing extrusion lines without any

problems.

Ettlinger Kunststoffmaschinen GmbH was founded in

1983 and is today a global player. The German company

has its headquarters in Königsbrunn, not far from Augs-

burg. Its core competency is the development and ma-

nufacture of injection moulding machines and high per-

formance melt filters. On the melt filtration side Ettlinger

makes high performance melt filters for continuous fil-

tration of heavily contaminated feedstock. Contami-

nants like paper, aluminium, wood, silicones, or high-

melting polymer composites can be removed from all

standard polymer materials.

Motan Colortronic (UK) Limited supports customers

in the UK and Ireland

Ettlinger’s new agent in the UK and Ireland is Motan Col-

ortronic Limited of Chesterfield, established in 1974.

With over four decades of experience, this Midlands

company supports injection molders, extruders, com-

pounders, blow molders and recyclers in the British Isles

with appropriate machinery and comprehensive, expert

services. Ettlinger’s high performance melt filters make

an ideal complement to this portfolio. A large and well-

stocked spares store and a Tech Center for application-

specific customer trials are available at the Chesterfield

site. Together with a decentralised network of service

specialists, they assure all-round field support for users,

carefully tailored to individual requirements.

Motan Colortronic (UK) Ltd

Matilda House, Carrwood Road, Chesterfield Trading Estate

Chesterfield, Derbyshire, S41 9QB, United Kingdom

www.motan-colortronic.co.ukECO High Performance Melt Filter

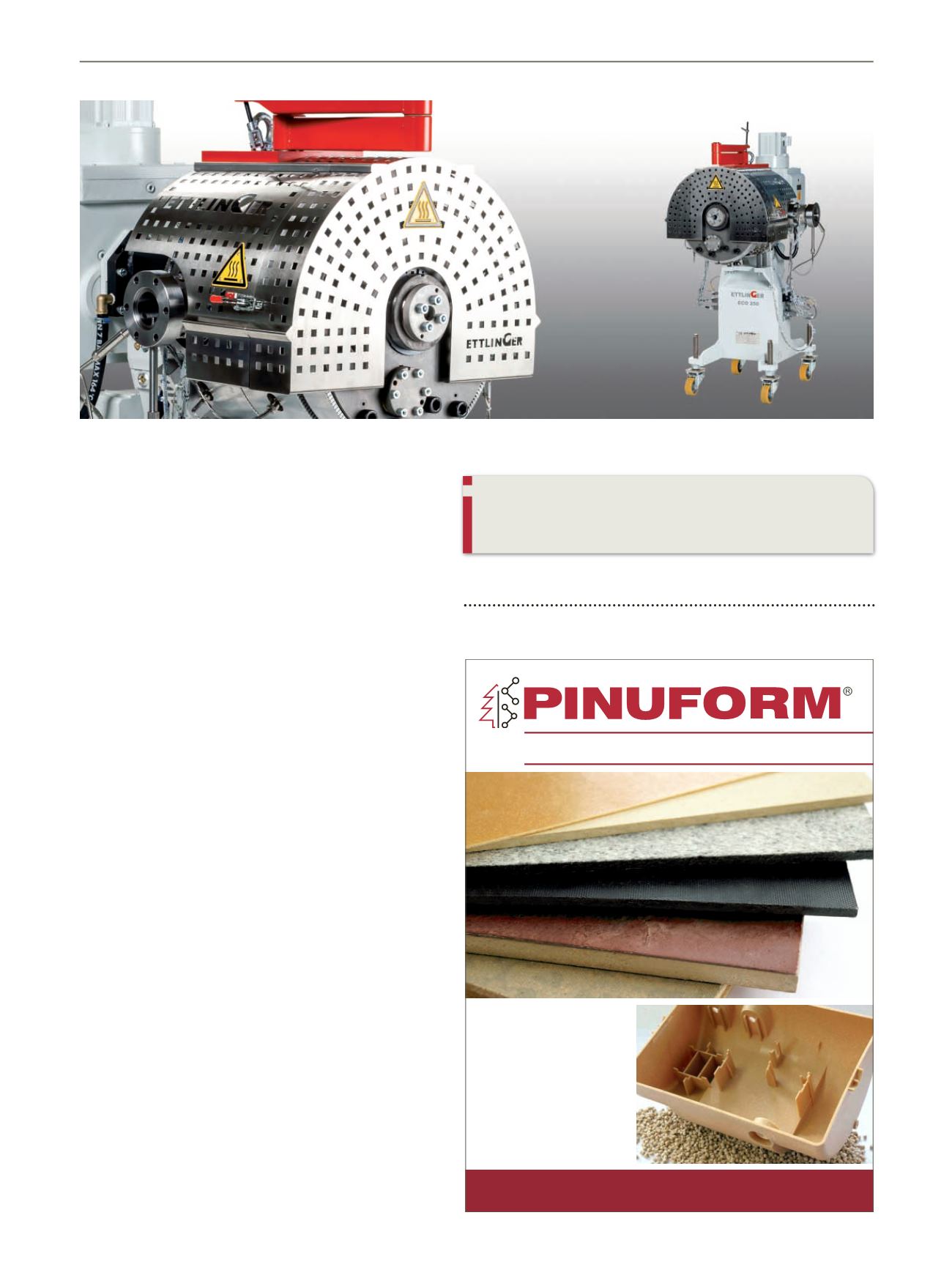

www.pinuform.deDas Unternehmen PINUFORM

ist ein Experte auf dem Gebiet

der WPC-Technologie.

Seit mehr als 10 Jahren ent-

wickeln und produzieren wir

hochwertige Produkte aus dem

erfolgreichen Verbundwerk-

VWRII 9RQ GHU +RO]IDVHU ÖEHU

die Granulatherstellung bis zur

Extrusion.

EIN WERKSTOFF MIT ZUKUNFT.